Conveyor systems have become increasingly critical for speedy, reliable production in a variety of industries. At their most basic, conveyor systems use a frame that supports a belt, rollers, or wheels to transport materials from one location to another. They are powered using a variety of methods, including electrical motors, manual actuation, or gravity. Conveyors…

The Role of Vision Inspection Systems in Cap Lining Technology

Vision inspection systems use cameras to automate visual inspections of products, identifying and separating defects while maintaining high productivity. Here, we’ll explore what vision inspection systems do and how they can be used for inspecting cap lining during production. What Are Vision Inspection Systems? Vision inspection systems are automated devices that use cameras, video, lighting,…

The Rise of Collaborative Robots: FANUC Cobot Integration

As human-robot interaction continues to grow, so does the need for safe and efficient collaborative robotics. Collaborative robots, otherwise known as cobots, are a type of robot that can safely and effectively work alongside human workers in various industrial and manufacturing settings. Unlike conventional robots, which are typically caged and require certain safety measures to…

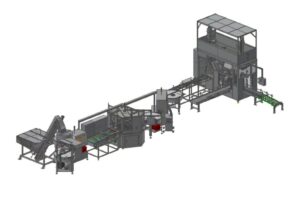

TYPES OF PARTS FEEDER SYSTEMS

At Big Sky Engineering, we specialize in the design, engineering, manufacturing, and integration of industrial automation equipment and systems. Our turnkey automation solutions include all necessary system elements, including parts feeders. The term “parts feeder system” refers to equipment that stores, sorts, orients, allocates, positions, and distributes the components necessary for industrial and commercial operations. As these units…

How to Calculate Equipment Operating Costs

When you purchase new equipment, the price tag is just the first expense your business will incur throughout its total service life. Before you purchase a big-ticket item—even when the equipment is meant to last for years—take the time to consider ancillary costs that will follow the purchase. Some of these basic cost factors may include:…

What is Flexible Manufacturing

The term “flexible manufacturing” refers to the ability of a company to adapt its production operations to produce different parts for different markets without the need for major retooling or equipment investment. Many companies utilize flexible manufacturing as a benchmark for where they stand in the industry; the greater their flexibility (i.e., how fast they…

What is Industrial Automation

Industrial automation uses computerized control systems and robots—i.e., automation machinery—to replace human decision-making and involvement in manufacturing processes. For example, automated machining tools and mobile components perform processing and finishing operations on materials, and automated conveyor systems move the parts and components through the various manufacturing stages. Benefits of Industrial Automation Due to the benefits…

A Guide to Cap Liners & Materials

Numerous closure and container cap liner materials exist for use with caps and closures on consumer products. The liner choice will impact the fit and function of the closure on the final packaging solution. Developing an understanding of the differences between lining cap materials will help to facilitate informed material choices. Importance of Container Cap…

New Innovations for Increased Efficiency

At CapTech Automation, our team continuously searches for ways to improve efficiency in the manufacturing sector. Drawing from the expertise of experienced industry professionals from Big Sky Engineering, we are able to produce advanced closure production machinery that enables our customers to integrate lean manufacturing principles into their operations easily and efficiently. By doing so,…

Lower Compressed Air Costs

Compressed air has recently become a valuable power source for a growing number of applications. It is often referred to as the fourth utility after water, electricity, and gas. However, compressed air can be potentially expensive in specific applications. When used inappropriately, wastage is significant, and the medium itself can become inefficient. Most high-speed cap…