For 25 years, the team at Big Sky Engineering, Inc. has specialized in comprehensive, innovative automation solutions at competitive prices. SCARA and Delta robots are two examples of automated equipment applicable for tasks such as palletizing and depalletizing, assembly line production, pick and place operations, and much more. Learn about these robots’ applications and advantages, and how Big Sky Engineering can help.

SCARA Robots

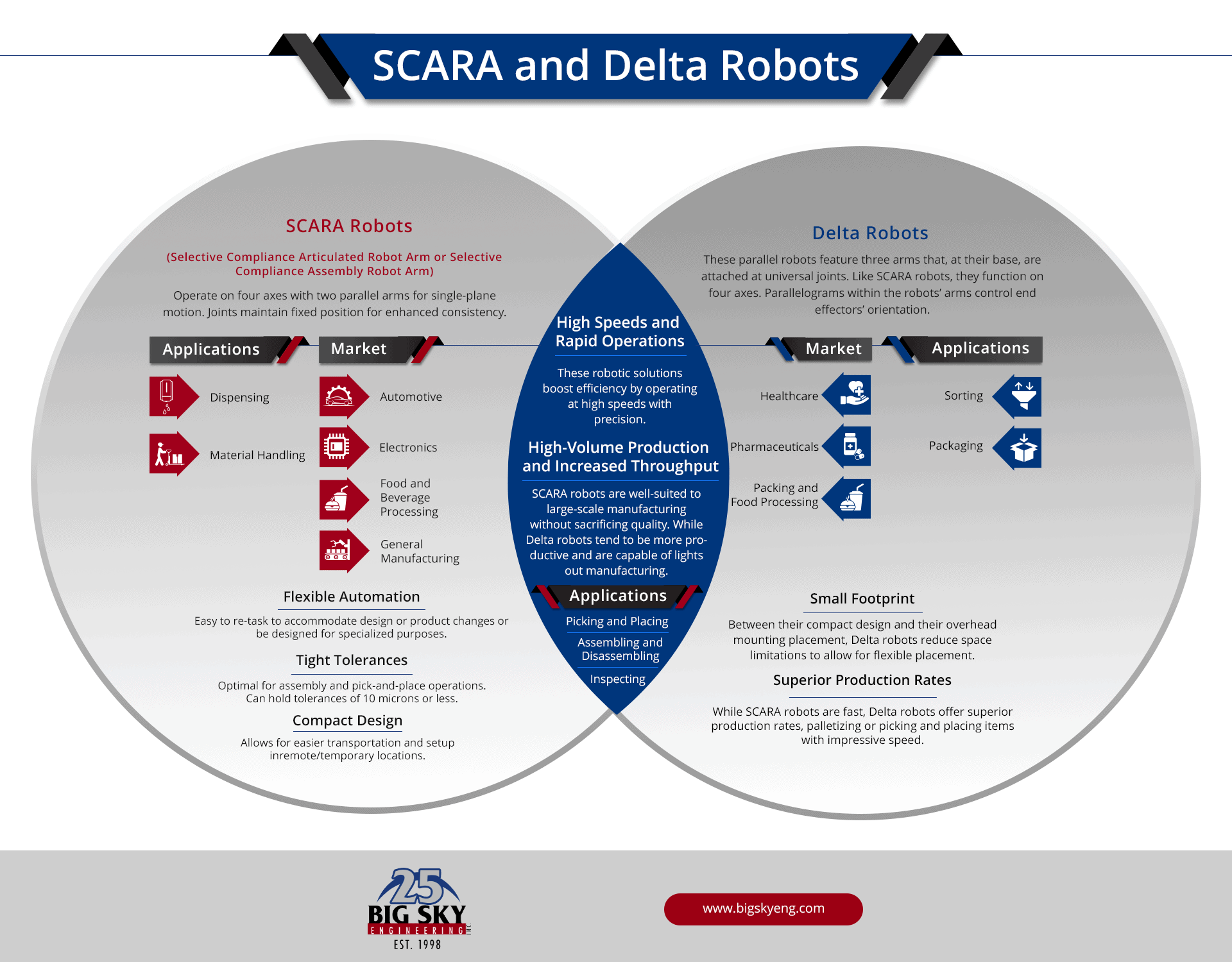

The term SCARA can stand for either Selective Compliance Articulated Robot Arm or Selective Compliance Assembly Robot Arm. SCARA robots typically operate on four axes, with their two parallel arms allowing for single-plane motion. These axes enable horizontal, vertical, and rotational movement. The final two axes sit at 90° angles in relation to the first two. Additionally, their joints maintain fixed positions to allow for enhanced consistency, establishing a single orientation within the robot’s cell or work area.

Applications

Many industries benefit from incorporating one or more SCARA robots in their operations. Markets like automotive, electronics, and food and beverage processing, not to mention general manufacturing, all have applications for these versatile machines, automating processes like:

- Dispensing

- Material Handling

- Picking and Placing

- Assembling and Disassembling

- Inspecting

Benefits

SCARA robots offer several key benefits that make them advantageous for the above applications. Their benefits include:

- High Speeds. These robotic solutions boost efficiency by operating at high speeds with precision.

- High-Volume Production. With increased speed comes increased productivity. SCARA robots are well-suited to large-scale manufacturing without sacrificing quality.

- Flexible Automation. Besides being highly versatile, SCARA robots are easy for manufacturers to re-task to accommodate design or product changes. They can also be designed for specialized purposes like cleanroom environments.

- Tight Tolerances. SCARA robots are optimal for assembly and pick-and-place operations because of their capacity for accuracy. They can hold tolerances of 10 microns or less, which is about half of what six-axis robots can achieve.

- Compact Design. These robots are ideal when you have minimal available floor space. Also, they allow for easier transportation and setup in remote or temporary locations.

Delta Robots

These parallel robots feature three arms that, at their base, are attached at universal joints. Like SCARA robots, they function on four axes. Parallelograms within the robots’ arms control end effectors’ orientation.

Applications

Delta robots serve industries ranging from healthcare and pharmaceuticals to packing and food processing — essentially any market in need of high-speed, efficient robotic solutions for repetitive tasks. Its applications overlap with those of SCARA robots somewhat, with potential applications for Delta robots including:

- Picking and Placing

- Sorting

- Assembling and Disassembling

- Soldering

- Inspecting

- Packaging

Benefits

Delta robots are popular solutions for many applications because of their specific advantages, including:

- Rapid Operation. While SCARA robots are fast, Delta robots offer superior production rates, palletizing or picking and placing items with impressive speed.

- Increased Throughput. Working at higher speeds enables Delta robots to be more productive. Additionally, these automated solutions are capable of lights-out manufacturing for round-the-clock operation.

- Enhanced Worker Safety. By handling the repetitive tasks that put stress on the human body, using Delta robots can help prevent worker injury.

- Small Footprint. Between their compact design and their overhead mounting placement, Delta robots reduce space limitations to allow for flexible placement.

Robotic Solutions From Big Sky Engineering

When you require fast, dependable robots for palletizing, assembly, pick-and-place tasks, and more, the team at Big Sky Engineering is here to help with innovative solutions. We offer high-speed, state-of-the-art robots that automate otherwise manual processes.

Based on your specific requirements, we’ll help you make the right robotics selection for your unique automation application. To learn more about our robotic products and incorporating automation into your operation, contact us to speak with one of our experts or request a quote today.