SITUATION

The customer desired a machine that would combine two food cup products with an output of

OPPORTUNITY & IMPLEMENTATION

The system will be capable of 100 parts per minute output.

Step 1: Product Infeed:

Cups enter the system on belted conveyors.

Step 2: Cup Assembly:

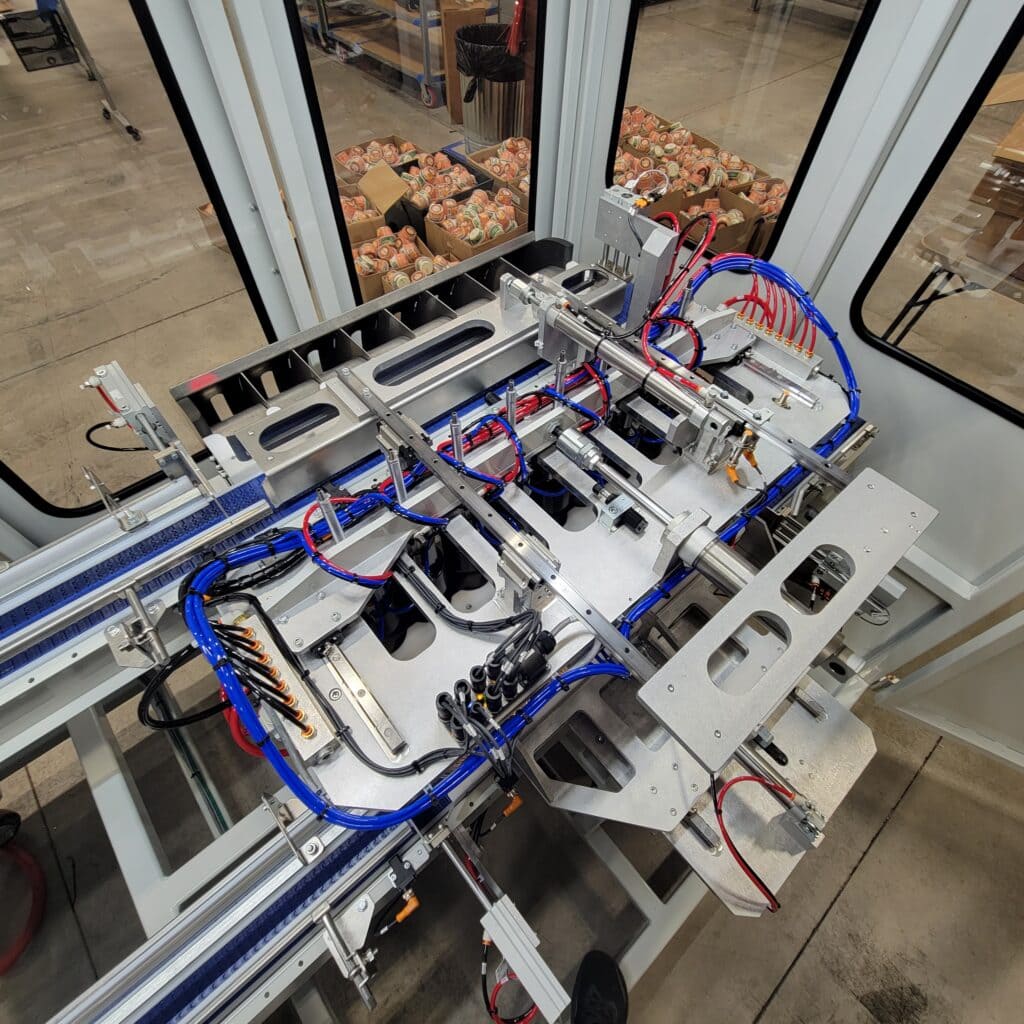

Actuators will side-shuttle a set of 8 cups perpendicular to be picked by a 2-axis pick-and-place mechanism.

This mechanism will use suction cups and guides to capture and locate the cups.

Step 3: Product Pack-Out:

The completed assemblies will be allowed to accumulate on another conveyor where thewill be picked for packaging. We will use a Fanuc LRMate robot with a custom vacuum end-of-arm-tool (EOAT) to pick an entire set of 8 cups and place them into the case.

DESIGN FEATURES & SPECIFICATIONS

Two Top cup infeed conveyors

Top cup escapements and cross-shuttle actuators

8-up transfer pick-and-place actuator

Bottom cup infeed conveyor

Custom feed screw for bottom cup location

PLC controls package and HMI

Approximate Machine Dimensions: 17’L x 5’W x 9’H

Power Requirements: 120 VAC, 1 Phase, 20A