SITUATION

The purchasing customer expressed the desire to expand its packaging operations for various closures. This presented an opportunity to create a faster automation line. The former antiquated process was slower using unpredictable equipment with slow output rates.

OPPORTUNITY & IMPLEMENTATION

The project requirements included the machine being completely autonomous. At its core, the requirements are a packaging rate of 600 parts per minute. The machine design will allow for various size closures to be run. The customer requested a modified design that would handle multiple closures ranging from 63mm to 70mm. The customer required the changeover procedure to be minimal and able to be performed in under 10 minutes. The finalized machine can package closures at a rate of 600ppm while surpassing all customer expectations.

Final Station Summary:

Closure In-Feed- Driven conveyors supply the machine with closures. The closures navigate through a twisting track on the interior of the machine to the cap stack module.

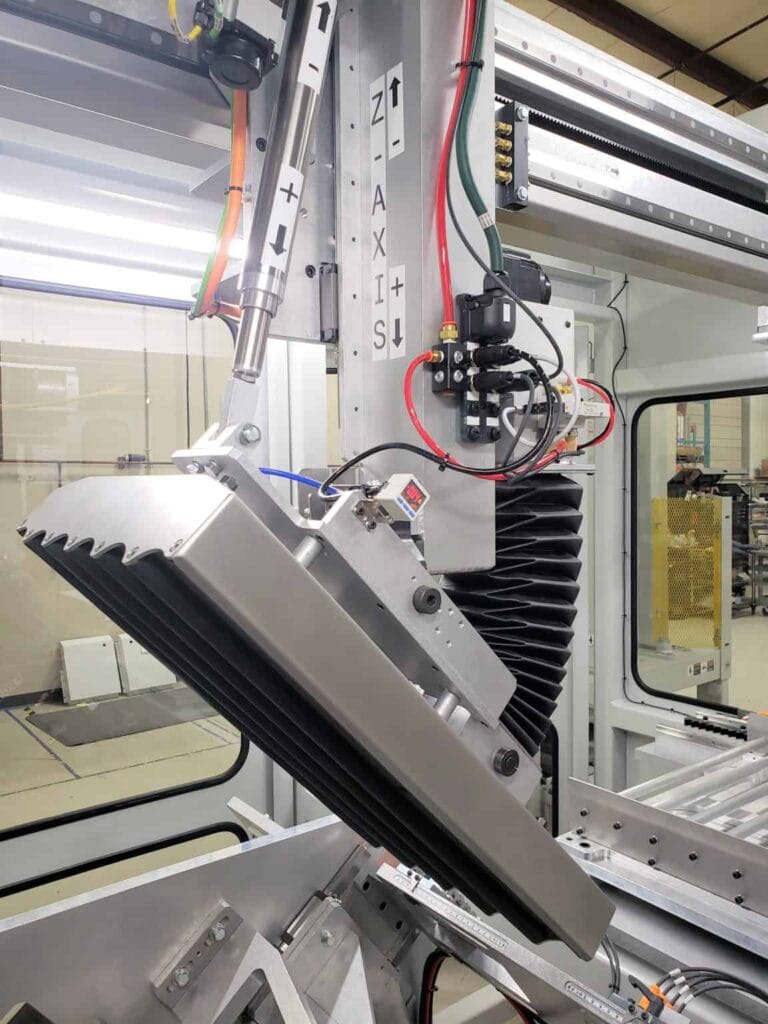

Cap Stack module- The cap stack module generates the (6) columns of caps by continuously up-stacking (4) layers of caps on an incline. The multiple axes of motion are all servomotor controlled. The cap stack module is capable of generating stacks all in the same orientation with cap nesting design features or opposing orientation as well as optional tooling

Vacuum Pickhead 1- The 3-axis pickhead picks and places 6 rows of stacked closures onto the gantry 1 transfer table, The cap pick head consists of the vacuum chamber designed to fit each cap size and configuration. The high-flow vacuum is generated using the intake of a powerful blower which is plumbed to the pick head.

Transfer Pickhead- The transfer pickhead transfers caps from the position 1 table to the array building table utilizing its high-flow vacuum system.

Pickhead 3 Case Loading- The same high-flow vacuum technology is used to capture either odd or even numbers of rows of caps from the indexing conveyor. The pick head will use a pneumatic actuator to expand or retract the pick head to change between odd and even rows.

Pallet Loading- A pallet magazine holds 15 pallets, and the included dispenser will release one pallet at a time on demand. An operator will manually load two 1/2 gaylord cases onto the pallet with the inserted bag cuffed around the exterior. Guides will aid the operator in the placement alignment of the cases. The pallet and gaylord will transfer into the load area.

Case Completion- Upon completion of the loading cycle, the box tilt will retract to a level position. Clamps and locates will return to the home position, and box conveyors will activate, transferring the box to the machine’s exterior and onto the out-feed conveyor.

DESIGN FEATURES & SPECIFICATIONS

- Multiple High Flow Vacuum Pickhead

- Integrated guard enclosure with interlocked doors

- Omron NX PLC controls the package

- Integrated Pallet Magazine

- 12-inch Pro-Face Touch screen

- Remote Pro-Face Touch screen

- Output is 600 CPM.

- Stack Light Indicators and audible alarms display the current machine state.

- The machine HMI uses customary pictures & buttons for control overrides. All machine sequences can be operated in manual mode on the HMI. Current cycle rates and station information is displayed on the main screen display

Approximate Machine Dimensions: 275”L x 338”W x 117”H

Power Requirements: 480VAC, 3 Phase, 100A

Pneumatic Requirements: 80PSI – 20 SCFM