At Big Sky Engineering, Inc., we’ve been building advanced custom automation and control systems since 1997. Our skilled engineers develop state-of-the-art industrial automation solutions and control panel designs that easily integrate with your existing plant floor operations.

We take full responsibility for all aspects of the design and manufacturing process, including:

- Hardware specifications

- Electromechanical–hydraulics installation

- HMI integration

- Testing

- Commissioning

- Documentation

- Training

How Does Custom Machine Automation Work?

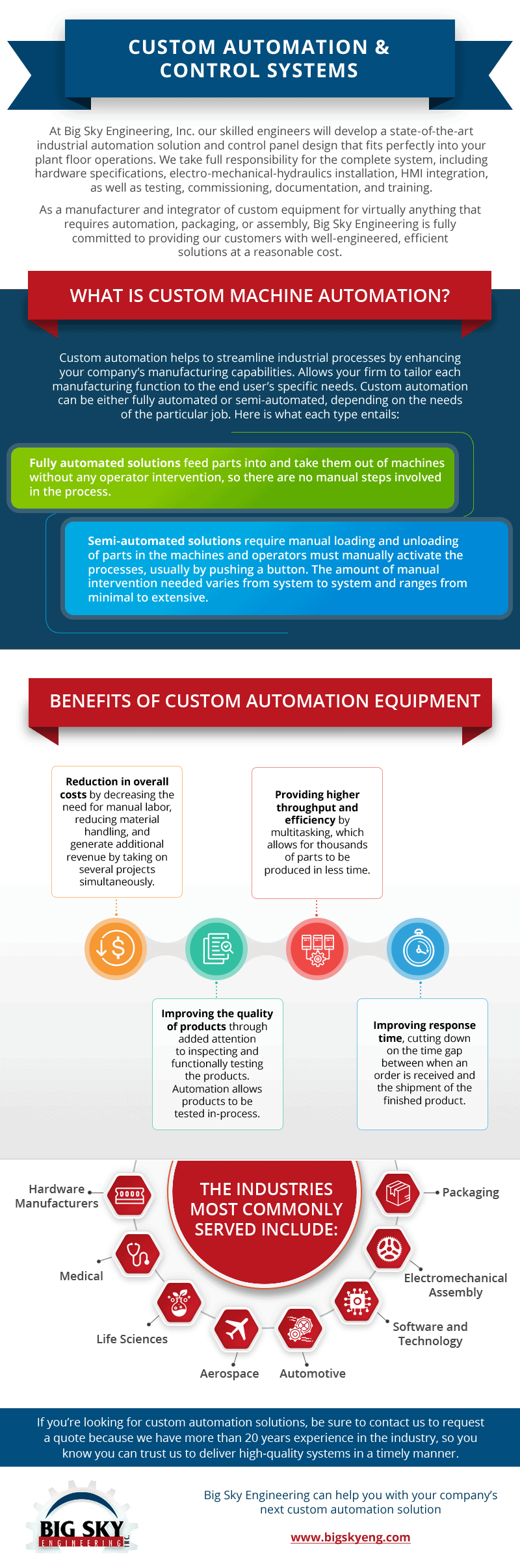

Custom automation helps streamline industrial processes by enhancing your company’s manufacturing capabilities. Custom machine automation allows your firm to tailor each manufacturing function to the end user’s specific needs.

Manufacturers can choose to either fully or partially automate their equipment depending on the needs of the particular job. Here’s what each type of automation entails:

- Fully automated solutions feed parts through machines without any operator intervention, eliminating the labor associated with manual operations.

- Semi-automated solutions require manual loading and unloading of parts in the machines, and operators must manually activate the processes, usually by pushing a button. The amount of manual intervention needed varies from system to system and ranges from minimal to extensive.

Manufacturers can install types of automation machines in their facilities, such as:

- Assembly machines, which drive automation systems and production lines. They’re highly efficient and have complete turnkey capabilities.

- High-speed closing machines, which offer consistency and reliability. These machines can be easily customized to accommodate several different hinge types.

- Inspection machines assess the accuracy of an assembly’s height, which guarantees that each part is the correct shape and size and has all its components.

- Integrated process machines are more complex, enabling them to combine multiple automation processes. These machines can accommodate several different tasks, including orientation and labeling.

- Testing machines fulfill several testing requirements, including leak, flow, and function tests.

- Laser tube cutting machines use lasers to cut and engrave a wide range of materials and sizes.

Benefits of Custom Automation Equipment

Some benefits of installing custom automation include:

- Reduction in overall costs by decreasing the need for manual labor, reducing material handling requirements, and allowing companies to generate additional revenue by taking on several projects simultaneously.

- Improved product quality through added attention to inspecting and functionally testing the products. Automation also allows products to be tested while processes are still running.

- Higher throughput and efficiency via effective multitasking, meaning that thousands of parts to be produced in shorter periods of time.

- Improved response time, which cuts down the time gap between when an order is received and the shipment of the finished product.

Common automation equipment includes:

- Laser measurement with trim and flash removal machinery, which picks two seals at a time and places them on a rotating spindle assembly.

- Shell assembly fixtures, which accommodate two different shell widths.

- Tank air pressure decay test fixtures, which make it easier to manually load tanks.

While every industry stands to benefit from effectively automating their equipment, these processes especially benefit businesses in the following fields:

- Packaging

- Electromechanical assembly

- Software and technology

- Automotive

- Aerospace

- Medical

- Hardware

Automate Your Way to Success

Custom automation streamlines manufacturing processes, allowing businesses to produce more products in shorter amounts of time and with less overhead. Big Sky provides top-quality automation services to clients across America. We draw from more than 20 years of experience to find the best solution for your needs.

If you would like to learn more about how we can help make your plant more efficient, contact us today.