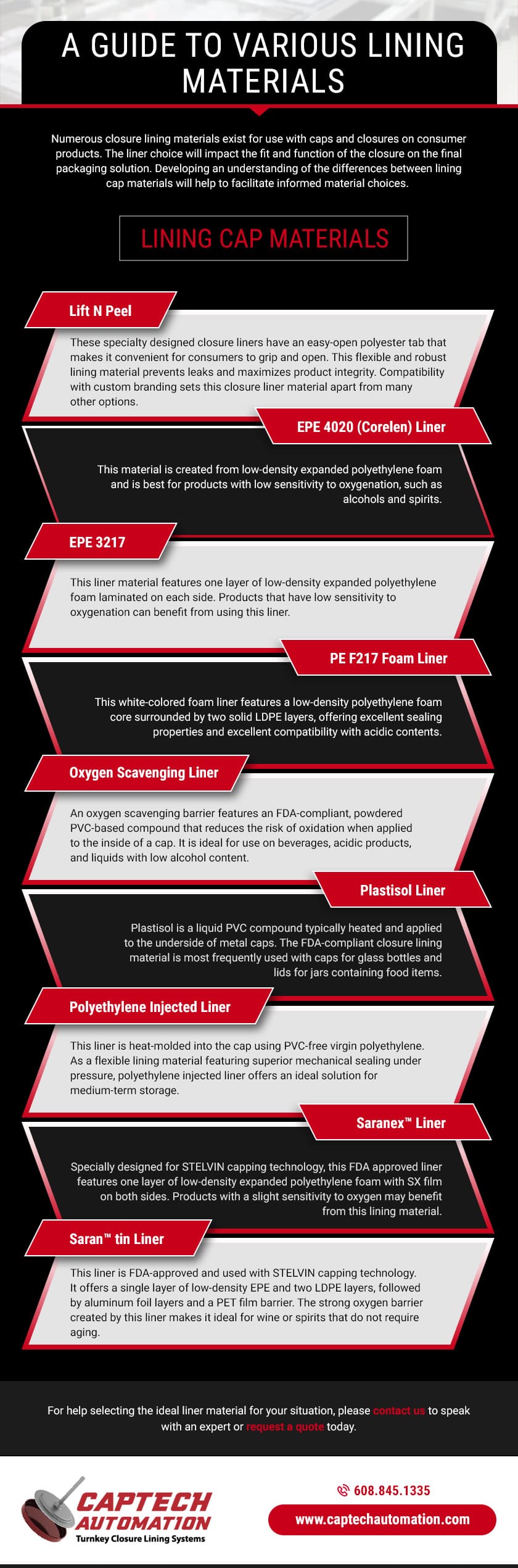

Numerous closure and container cap liner materials exist for use with caps and closures on consumer products. The liner choice will impact the fit and function of the closure on the final packaging solution. Developing an understanding of the differences between lining cap materials will help to facilitate informed material choices.

Importance of Container Cap Liner Materials

A cap liner serves as a barrier between the cap and the container’s contents, providing an additional seal for the finished product. The liner helps maintain product integrity during transport and throughout any time spent on the retail shelf. The lining cap remains in direct contact with the product’s contents, so chemical compatibility must factor into material selection.

The liner may directly affect the product’s integrity, so it’s essential to choose the best liner possible. The liner also helps protect brand integrity by providing consumers with evidence that the product has not been tampered with before purchase.

Container Cap Liner Material Options

Various lining cap materials offer different properties that make each beneficial for specific application types. The three main categories of plastic closures include cellulosic, foil, and extruded polymer. Within these categories, here are some of the most common choices for container cap liner materials:

- Lift N Peel. These specialty designed closure liners have an easy-open polyester tab that makes it easy for consumers to grip and open. This flexible and robust lining material prevents leaks and maximizes product integrity. Compatibility with custom branding sets this closure liner material apart from many other options.

- EPE 4020 (Corelen) liner. This material is created from low-density expanded polyethylene foam and is best for products with low sensitivity to oxygenation, such as alcohols and spirits.

- EPE 3217. This liner material features one layer of low-density expanded polyethylene foam laminated on each side. Products that have low sensitivity to oxygenation can benefit from using this liner.

- PE F217 foam liner. This white-colored foam liner features a low-density polyethylene foam core surrounded by two solid LDPE layers, offering excellent sealing properties and excellent compatibility with acidic contents.

- Oxygen scavenging liner. An oxygen scavenging barrier features an FDA-compliant, powdered PVC-based compound that reduces the risk of oxidation when applied to the inside of a cap. It is ideal for use on beverages, acidic products, and liquids with low alcohol content.

- Plastisol liner. Plastisol is a liquid PVC compound typically heated and applied to the underside of metal caps. The FDA-compliant closure lining material is most frequently used with caps for glass bottles and lids for jars containing food items.

- Polyethylene injected liner. This liner is heat-molded into the cap using PVC-free virgin polyethylene. As a flexible lining material featuring superior mechanical sealing under pressure, polyethylene injected liner offers an ideal solution for medium-term storage.

- Saranex™ liner. Specially designed for STELVIN capping technology, this FDA approved liner features one layer of low-density expanded polyethylene foam with SX film on both sides. Products with a slight sensitivity to oxygen may benefit from this lining material.

- Saran™ tin liner. This liner is FDA-approved and used with STELVIN capping technology. It offers a single layer of low-density EPE and two LDPE layers, followed by aluminum foil layers and a PET film barrier. The strong oxygen barrier created by this liner makes it ideal for wine or spirits that do not require aging.

Container Cap Liner Material Applications

A variety of products use liner materials in their caps and lids, such as:

- Beer, wine, and spirits

- Food and beverage

- Household products

- Cosmetics

Contact CapTech Automation for Container Cap Liner Material Expertise

Choosing the right lining cap material is essential for maintaining product quality. With the long list of container cap liner materials, it can be hard to determine the one best suited to a specific application. For help selecting the ideal liner material for your situation, please contact us to speak with an expert or request a quote today.