SITUATION

The purchasing customer expressed the desire to expand into a new state-of-the-art production facility. This presented an opportunity to automate valve packaging and part inspection assemblies, ensuring a more consistent outcome by accurately regulating variability and improving processes while generating cost savings. The former antiquated process was predominantly manual and required a high degree of physical tasks and close monitoring.

OPPORTUNITY & IMPLEMENTATION

The project requirements included the machine to be completely autonomous. At its core, the requirements of this project required complex part inspection with a packaging rate of 15PPM. The Machine changeover is not to surpass 10 minutes. The HMI (Human Machine Interface) must be programmed for multiple recipes. All machine guarding was required by NFPA 79 and OSHA standards. The machine was equipped with strategic service areas. The control system was UL-certified. All equipment met NEC standards as specified by the customer.

Final Stations Include:

Valve Part In-Feed- A driven conveyor supplies the machine with valve parts.

Valve Guide Pick- The Fanuc robot picks the part with a parallel jaw gripper. The robot positions the parts in the camera and micrometer inspection stations.

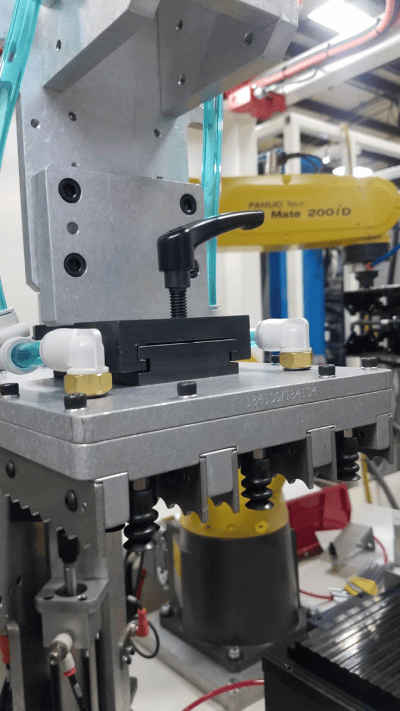

Micrometer- a digital micrometer checks the Edge and inner part for flaws and inconsistencies. Rejected parts are placed in the reject chute located on the top of the machine table.

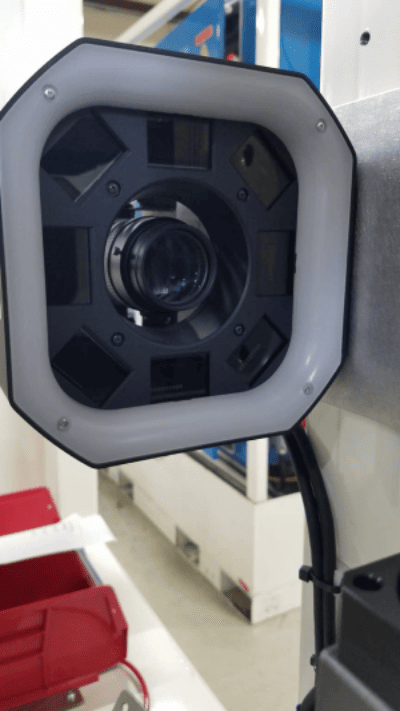

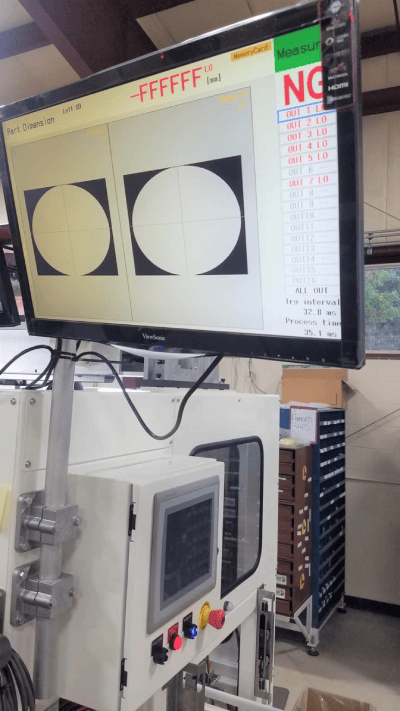

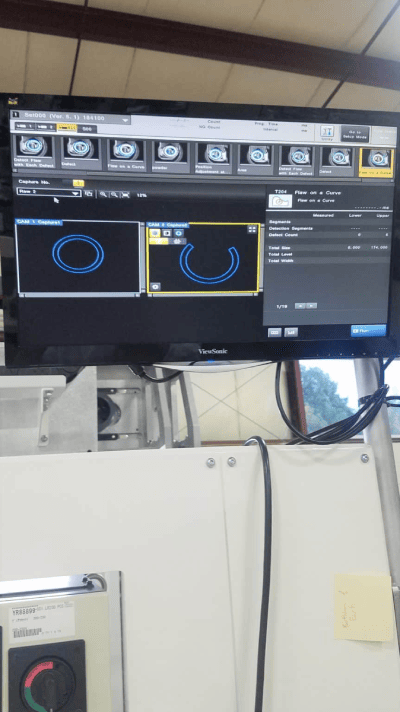

Camera Inspection- The camera inspection scans the part edge for flaws and inconsistencies. Rejected parts are placed in the reject chute located on the top of the machine table.

Array Building Table- Parts that pass inspection are placed on the array building table.

Part Transfer- The parts are picked from the array building table by a vacuum pickhead, The gantry then positions the pickhead into the case.

Case Handling- The cases are transferred into the box loading zone by powered roller conveyors. When the empty case advances in the case packing zone, box corner clamps secure the box into position. Vertical Clamps and locates will hold the case with plastic lining installed into position. When the cycle is completed, and the case is filled. Inspection Display Screens- Inspection display screens are located on the exterior of the machine. The displays give live results of the machine.

DESIGN FEATURES & SPECIFICATIONS

- Fanuc LR Mate 200iD utilizes a rotating swivel head with a gripper tool to pick and place valve components.

- Keyence TM-040 Optical Micrometers.

- Keyence Defect Camera Inspection System.

- The HMI (Human Machine Interface) features dual language display capabilities.

- 4 second Cycle time.

- Stack Light Indicators and illuminated control buttons signal the machine operator of the machine’s current state.

- The machine HMI uses customary pictures & buttons for control overrides. All machine sequences can be operated in manual mode on the HMI.

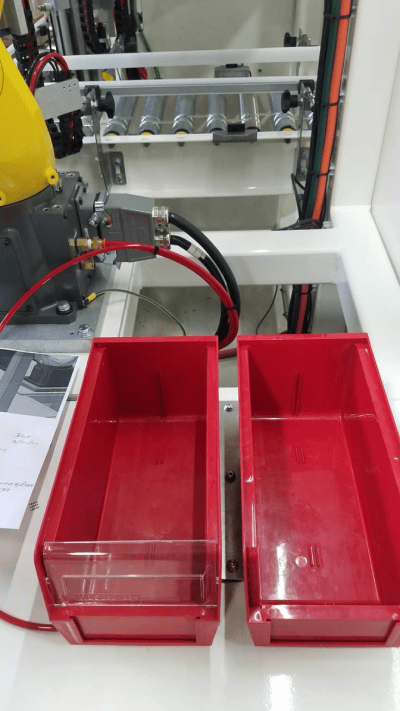

- The reject bin located inside the machine table prevents the operator and bystanders from machine hazards.

- Powered roller conveyors

- Allen Bradley PLC controls package and HMI

Approximate Machine Dimensions: 114”L x 60”W x 93”H

Power Requirements: 480VAC, 3 Phase, 30A

Pneumatic Requirements: 80PSI – 30 SCFM