SITUATION

The purchasing customer desired a clamshell machine to count and package 100+ hardware, including placing pamphlet information into the blister packs. The basic machine requirements include an automatic wallet blister card feeder, automatic pill pack product feeder, HMI/PLC touch screen control, and Options for robotic unloading.

OPPORTUNITY & IMPLEMENTATION

The proposed and final stations include:

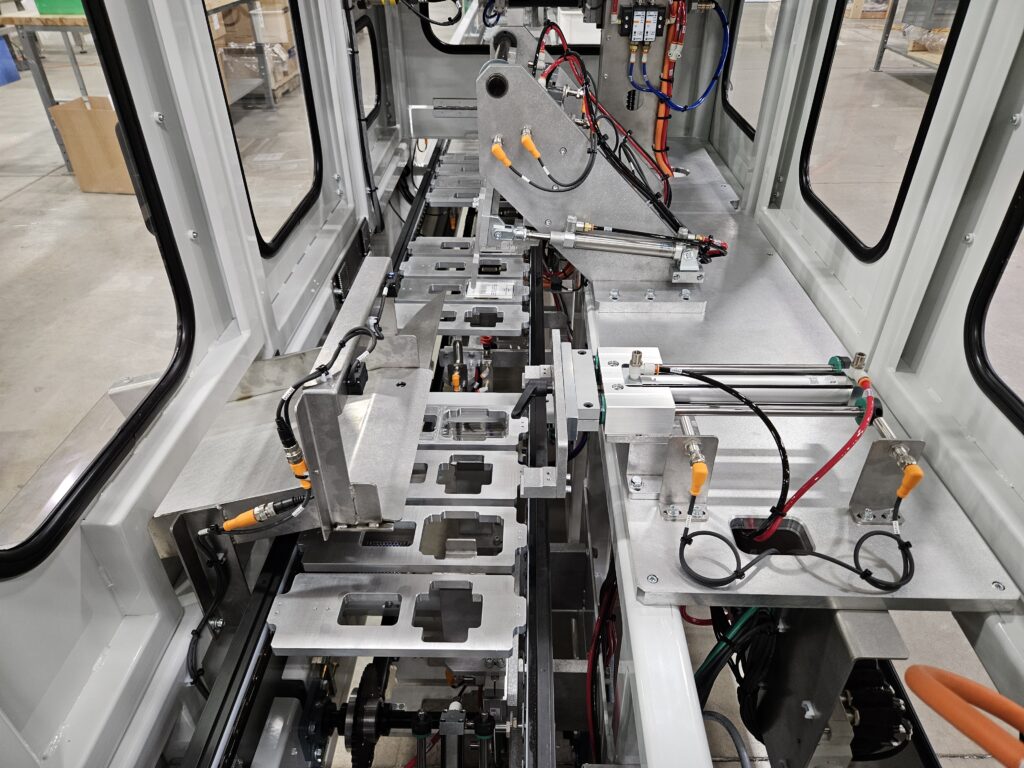

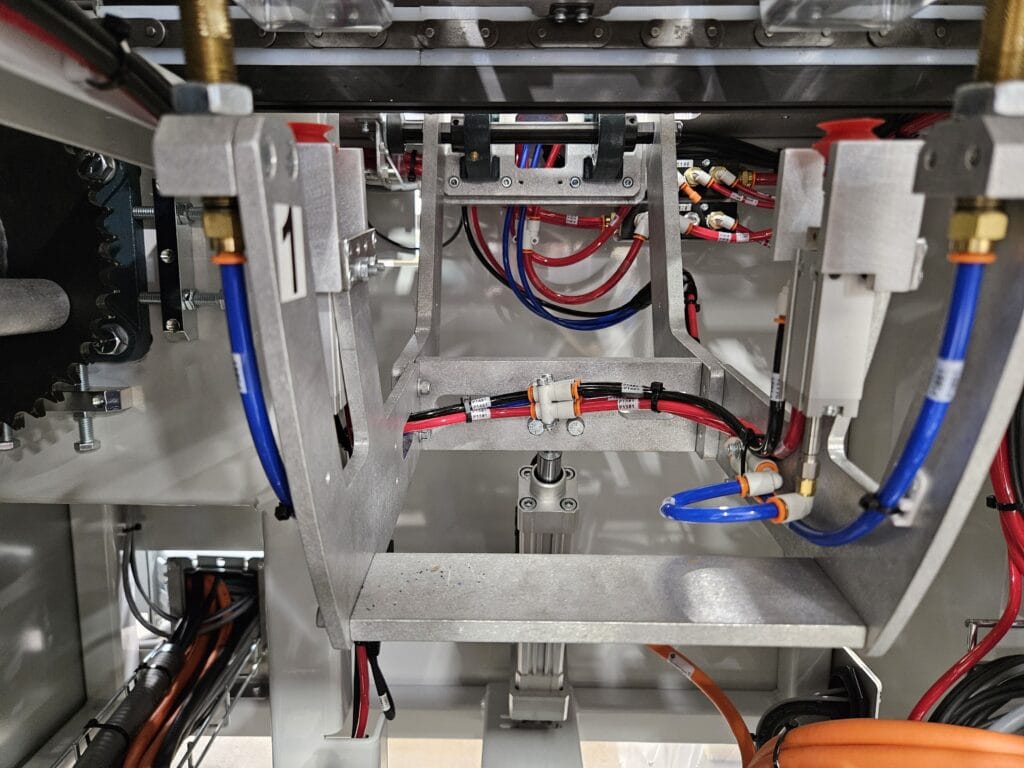

Indexing Conveyor- The index position will be controlled using a servo motor and gearbox.

Clamshell Denester- This proven and very effective denester design is specifically engineered for clamshell blisters. Two clamshells will be denested at a time and placed into the indexing carrying

trays. The pick mechanism rises through the carrying tray and engages the clamshells from the bottom with vacuum and returns depositing the blisters in the carrying trays.

Filling– Batching Systems and manual filling stations integrated.

Card Placing Station- . The station plucks two cards simultaneously and place them into the bottom of the clamshells

Lid Closing Station- The lids are then pneumatically snapped shut with two independent closer bars. Independent bars prevent one unclosed box from allowing the other to not lock.

Unload- The packages enter the second unload station, the packages are orientated on the packaging in-feed conveyor.

DESIGN FEATURES & SPECIFICATIONS

- Class 3 guard enclosure.

- Output: 80 PPM.

- Stack Light Indicators display the current machine state.

- Allen-Bradley 10” PanelView HMI

- The machine HMI uses customary pictures & buttons for control overrides. All machine sequences can be

operated in manual mode on the HMI. Current cycle times are displayed on the HMI.

Approximate Combined Machine Dimensions: 20”L x 8’W x 8’H

Filling & Labeling Power Requirements: 480VAC, 3 Phase, 30A

Pneumatic Requirements: 80PSI – 9 SCFM