Custom Inspection Systems

Vision systems are paramount in automation as they enable machines to perceive and interpret their surroundings akin to human vision. By employing cameras and advanced image processing algorithms, vision systems can inspect, identify, and guide machinery in real-time, ensuring precision and accuracy in manufacturing processes. This technology not only enhances efficiency but also facilitates quality control, error detection, and adaptability in various industrial settings, leading to increased productivity and reduced downtime. Harnessing the power of vision systems empowers automation to operate with heightened sophistication and reliability, driving innovation and competitiveness in modern industries.

Custom Inspection Systems

Vision systems are paramount in automation as they enable machines to perceive and interpret their surroundings akin to human vision. By employing cameras and advanced image processing algorithms, vision systems can inspect, identify, and guide machinery in real-time, ensuring precision and accuracy in manufacturing processes. This technology not only enhances efficiency but also facilitates quality control, error detection, and adaptability in various industrial settings, leading to increased productivity and reduced downtime. Harnessing the power of vision systems empowers automation to operate with heightened sophistication and reliability, driving innovation and competitiveness in modern industries.

Benefits of Inspection Systems

What Are Vision Inspection Systems?

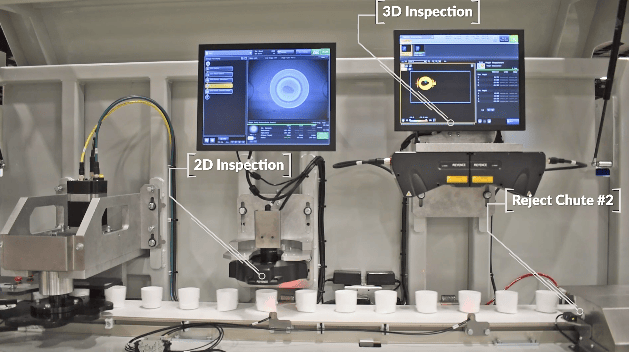

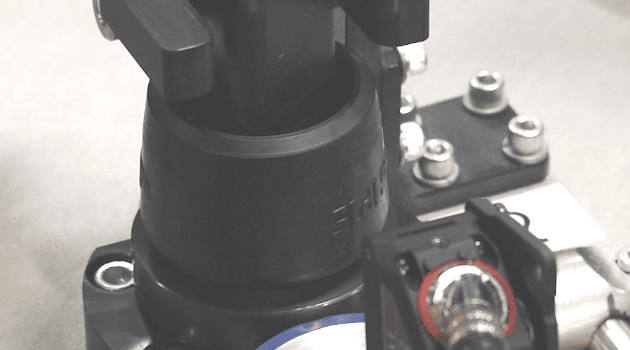

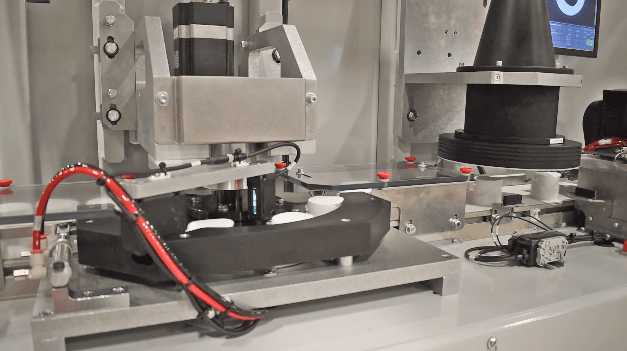

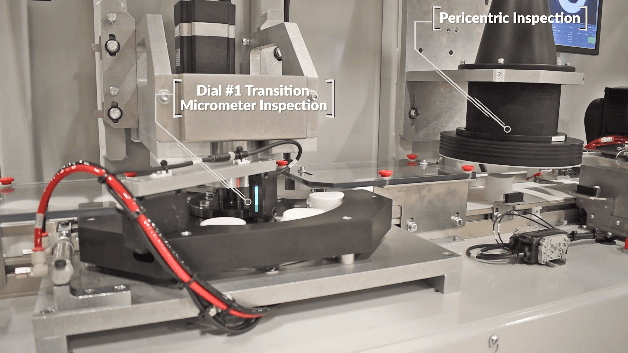

In manufacturing operations, vision inspection systems—sometimes called machine vision systems—are used to detect and identify defects visually. They help ensure products meet the specifications outlined in the design and the quality standards defined by the manufacturer/customer.

How Do Vision Inspection Systems Work?

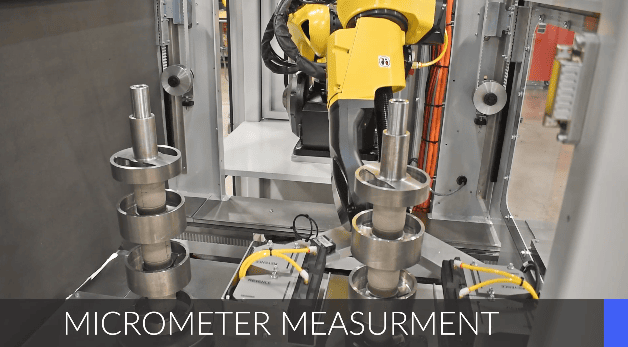

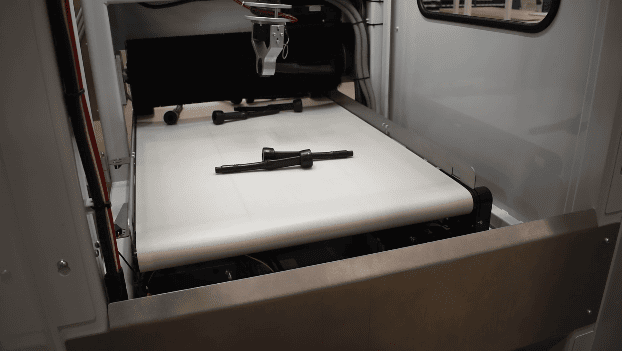

Vision inspection systems use a camera or multiple cameras along with video and lighting components to measure parts, validate necessary components, and verify workpiece positioning. While basic systems require human operators to analyze the data they collect about products and make decisions accordingly, more advanced systems use computer software to automate the response to when a defect is detected.

Benefits of Vision Inspection Systems

There are many benefits to integrating vision inspection systems into a manufacturing facility, such as:

- Better part/process quality. Adding vision inspection systems to a production line reduces the risk that parts and products distributed to customers do not meet the necessary specifications and standards. Additionally, the information about parts and processes collected by the systems can be used to improve future production operations.

- Faster production speeds/shorter lead times. Vision inspection systems enable manufacturers to speed up production operations without increasing the risk of defective products going out to customers, which helps decrease lead times for product orders.

- Higher production yields. Since vision inspection systems allow for faster production speeds without sacrificing product/process quality, more units can be manufactured within the same timeframe.

- Lower production costs. Combining automated vision inspection systems with robotic manufacturing units enables products to be produced with fewer workers, resulting in lower labor costs.

- Safer worker conditions. Manufacturing operations often involve exposure to potentially hazardous materials and/or conditions. Vision inspection systems eliminate the need for human workers to handle manufactured objects directly, enabling them to avoid health and safety hazards.

- Greater customer satisfaction. Both better product quality and shorter lead times increase customer satisfaction.

Applications for Vision Inspection Systems

Vision inspection systems find use in the manufacturing operations of nearly every industry. In addition to detecting product defects, other typical applications for these systems include:

- Identifying the absence/presence of targeted elements

- Matching patterns

- Reading barcodes and other unique product codes

- Recognizing/verifying optical characters or colors

- Sorting objects based on selected characteristics

Industries Using Inspection Systems

- Aero & Defence

- Agriculture

- Automotive

- Chemical

- Construction

- Electronics

- Food and Beverage

- Govt & Military

- Medical & Health

- Metals

- Oil & Gas

- Plastics & Rubber

- Textiles and Apparel

Industrial Robotics From Big Sky Engineering

At Big Sky Engineering, we create flexible automation solutions using the most advanced robotic technology. Whether you need a solution for robotic palletizing, conveyor systems, or another application, our team can create a superior system that addresses all of your requirements. To learn more about our industrial robotics, contact our team or request a quote today.