SITUATION

A large united states automotive manufacture was in need of a machine to weld and laser mark automotive seat components. The machine requirements included utilizing two Yasakawa robots.

OPPORTUNITY & IMPLEMENTATION

The proposed and final stations include:

Product Loading/Offload- The product load/offload station features safety light curtains and LED indicators to instruct the machine operator.

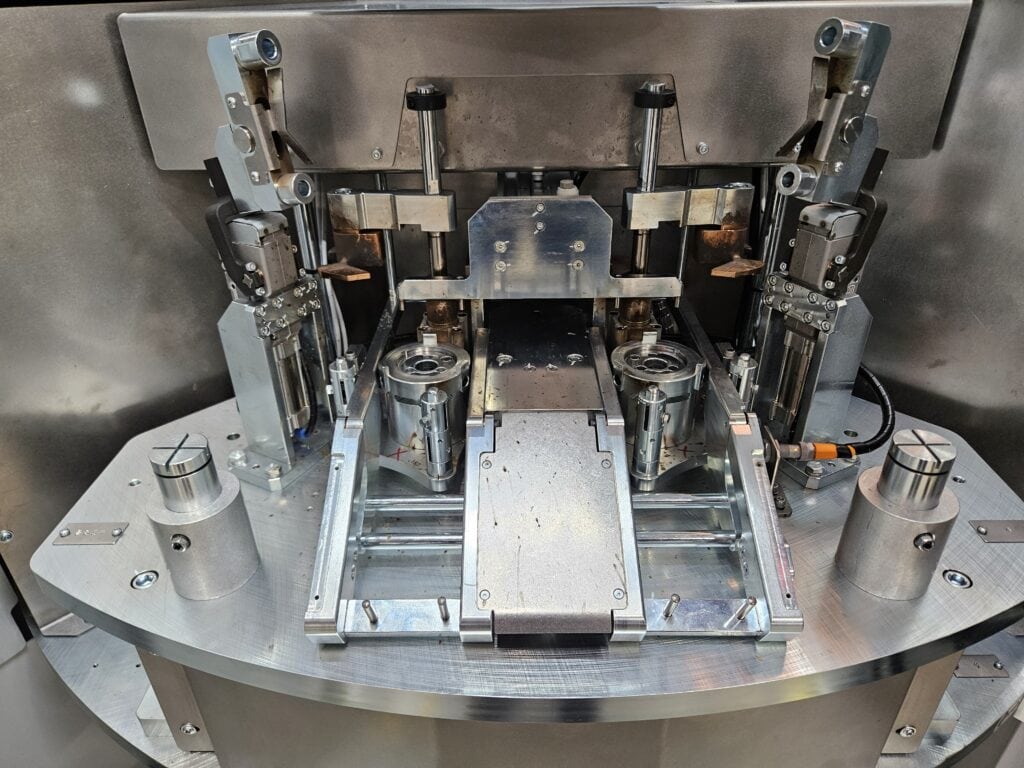

Laser Marking- Product QR codes are laser marked onto the part.

Welding– Two Yawasaka robots seamlessly weld two components in the machine fixture.

3D Vision- 3-D vision systems inspect parts for quality assurance.

DESIGN FEATURES & SPECIFICATIONS

- Class 3 guard enclosure.

- Output: 80 PPM.

- Stack Light Indicators display the current machine state.

- Allen-Bradley 10” PanelView HMI

- The machine HMI uses customary pictures & buttons for control overrides. All machine sequences can be

operated in manual mode on the HMI. Current cycle times are displayed on the HMI.

Approximate Combined Machine Dimensions: 10”L x 10 ’W x 8’H

Pneumatic Requirements: 80PSI – 9 SCFM