Robotic palletizing systems use state-of-the-art technology to help automate palletizing operations for warehouses, production lines, and manufacturing facilities, creating a seamless process from start to finish. Palletizing robots are the key to automated palletizing, as they handle various materials such as pallets, slip sheets, and tier sheets.

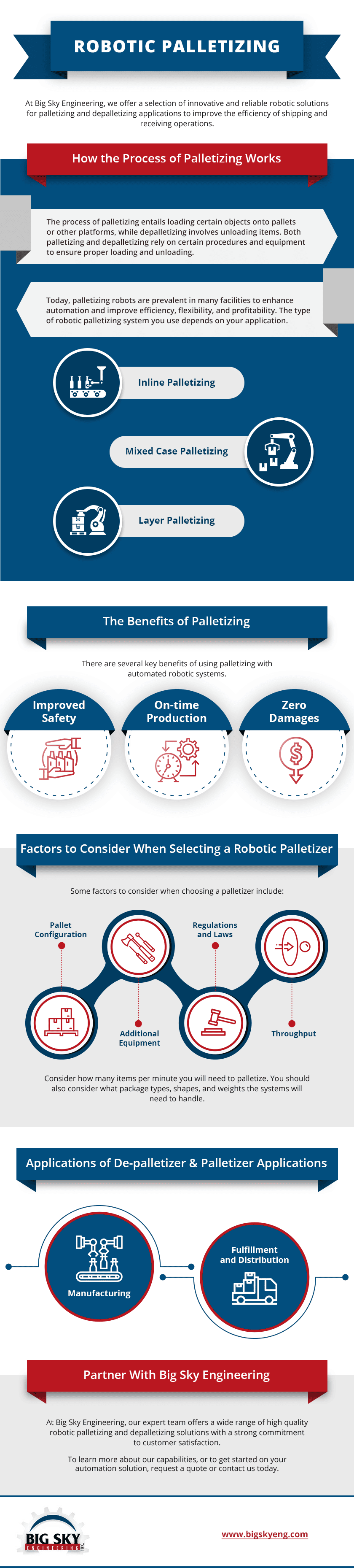

At Big Sky Engineering, we offer a selection of innovative and reliable robotic solutions for palletizing and depalletizing applications to improve the efficiency of shipping and receiving operations.

How the Process of Palletizing Works

The process of palletizing entails loading certain objects onto pallets or other platforms, while depalletizing involves unloading items. Both palletizing and depalletizing rely on certain procedures and equipment to ensure proper loading and unloading.

Today, palletizing robots are prevalent in many facilities to enhance automation and improve efficiency, flexibility, and profitability. The type of robotic palletizing system you use depends on your application.

Inline Palletizing

Robotic palletizing systems are available for inline palletizing applications at the end of the line. They synchronize with the speed of the production line conveyor to maintain efficiency and consistency, while working to prevent collisions between packages. Following the completion of a layer, the end stop lowers and the palletizing layer moves toward the robot, which picks up and places the package on a pallet with accuracy.

Mixed Case Palletizing

For applications with items of varying materials and dimensions, a mixed case robot palletizing system is available. These systems use robotic palletizers that can adapt to changes in orders, containers, and articles to minimize errors and maintain efficiency.

Layer Palletizing

If you need optimal control over palletizing processes that handle a wide variety of products and packaging types, a reliable layer picking solution can help. A layer palletizing system can utilize a roll-up palletizing method and can handle many types of packages including cardboard.

The Benefits of Palletizing

There are several key benefits of using palletizing with automated robotic systems.

Improved Safety

Through the use of automated robotics, you can make your facilities safer by eliminating many manual tasks that put workers at risk of injuries, such as tears, strains, and sprains, due to heavy lifting or repetitive motion.

On-time Production

Robotics maintain efficiency throughout the palletizing process by using precise configurations and cutting edge technology, making them faster than manual labor. Subsequently, you can ensure your operations remain productive and timely.

Zero damages

Increased accuracy and precision across palletizing operations minimizes room for error, allowing for more consistent results that you won't find with human-operated systems.

Factors to Consider When Selecting a Robotic Palletizer

Some factors to consider when choosing a palletizer include:

Pallet Configuration

Pallet configuration plays a big part in determining which system is best. Aspects of configuration may include:

- Layer configuration on the pallet

- The total number of pallet layers

- Whether the application will use slip sheets or tier sheets

- The rotation of each layer's configuration

Additional Equipment

In addition to palletizers, other equipment may be needed to transport pallets, such as pallet dispensers, shrink wrappers, and other machinery or manual systems.

Regulations and Laws

Prior to installing a robotic palletizing system, you need to consider the various laws and regulations in place, according to the state, corporation, and municipality in which the system will be installed.

Throughput

Consider how many items per minute you will need to palletize. You should also consider what package types, shapes, and weights the systems will need to handle.

Applications of De-palletizer and Palletizer Applications

There are two main applications for palletizing and depalletizing systems.

Manufacturing

Manufacturers depend on reliable palletizing systems to meet their package handling and loading needs, whether for individual or bulk packages.

Fulfillment and Distribution

Robotic palletizers and depalletizers offer an efficient and reliable option for building and breaking down various packages to prepare them for order fulfillment and distribution.

Partner With Big Sky Engineering

Automated robotic systems are an invaluable asset to your shipping and receiving operations. At Big Sky Engineering, our expert team offers a wide range of high quality robotic palletizing and depalletizing solutions with a strong commitment to customer satisfaction. To learn more about our capabilities, or to get started on your automation solution, request a quote or contact us today.