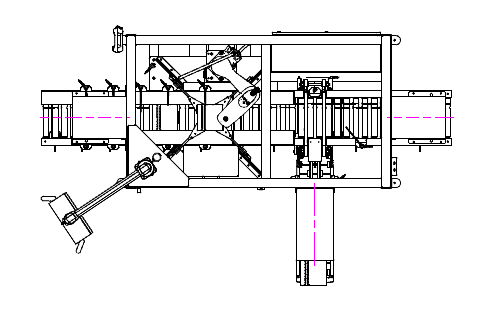

This machine was developed for a customer who receives constant shipments and needs the shipping boxes to be cut open on three sides for easy access to the box’s contents. The lid needed to remain with the opened box so the shipping label could be verified against the contents. This project also had to be developed to work without any compressed air.

The infeed conveyor allows for up to 4 boxes to be accumulated by an operator, and will automatically feed the boxes one at a time as needed. The machine also has downstream detection to pause when the line is backed up. The main conveyor through the machine uses a zero-pressure accumulation method to control the box locations.

As a box enters the machine, a servo-controlled clamp centers the box and holds it securely in place. A Fanuc SR-6iA robot then cuts three sides of the box. The cutting tool uses a standard utility blade and does not require any tools to change blades.

If there is a problem cutting the box or the blade breaks, the machine will detect the error and the box will be rejected. A separate reject queue allows up to three boxes to accumulate before stopping the machine.

Approximate Machine Dimensions: 135”L x 83”W x 103”H

Power Requirements: 480VAC, 3 Phase, 60 Hz, 30A

Pneumatic Requirements: N/A