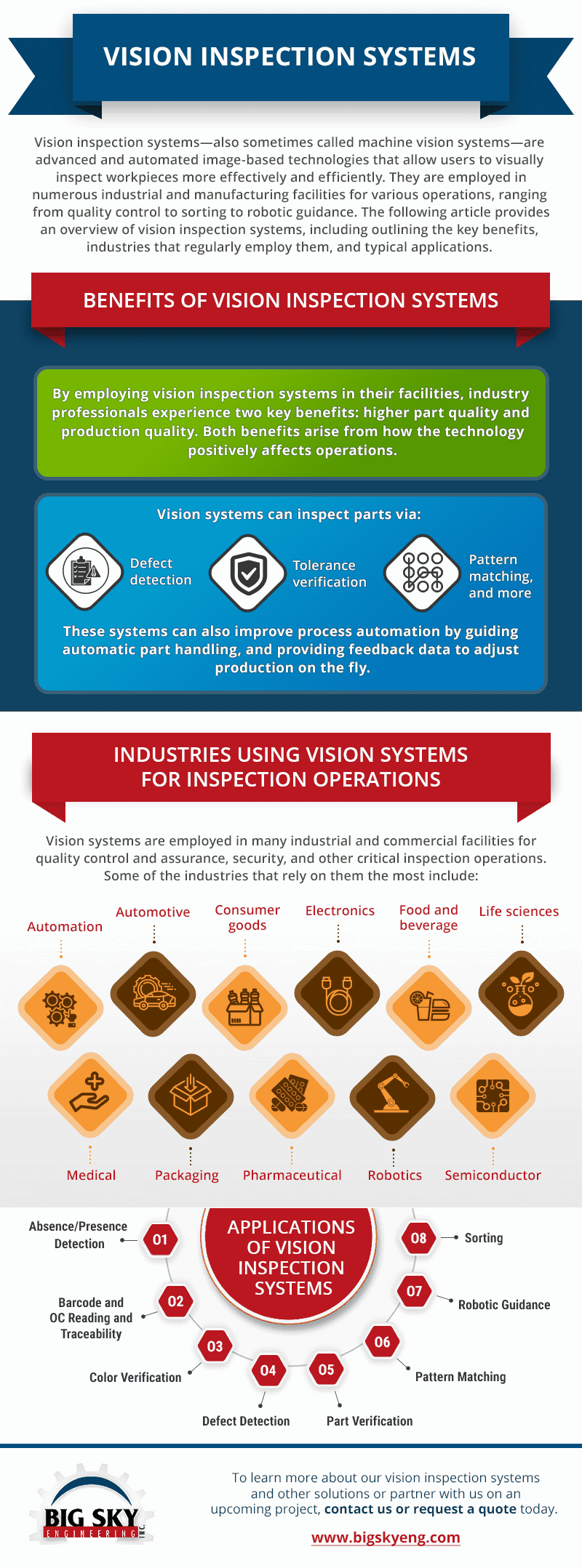

Vision inspection systems—also sometimes called machine vision systems—are advanced and automated image-based technologies that allow users to visually inspect workpieces more effectively and efficiently. They are employed in numerous industrial and manufacturing facilities for various operations, ranging from quality control to sorting to robotic guidance. The following article provides an overview of vision inspection systems, including outlining the key benefits, industries that regularly employ them, and typical applications.

BENEFITS OF VISION INSPECTION SYSTEMS

By employing vision inspection systems in their facilities, industry professionals experience two key benefits: higher part quality and production quality. Both benefits arise from how the technology positively affects operations. More specifically, it facilitates part inspection—including defect detection, tolerance monitoring, and component measuring—and process automation—including automatically handling parts and performing processes, providing feedback data, and adjusting accordingly.

INDUSTRIES USING VISION SYSTEMS FOR INSPECTION OPERATIONS

Vision systems are employed in many industrial and commercial facilities for quality control and assurance, security, and other critical inspection operations. Some of the industries that rely on them the most include:

- Automation

- Automotive

- Consumer goods

- Electronics

- Food and beverage

- Life sciences

- Medical

- Packaging

- Pharmaceutical

- Robotics

- Semiconductor

APPLICATIONS OF VISION INSPECTION SYSTEMS

Within the above industries, vision inspection systems are utilized in many different operations to improve efficiency, including the following:

- Absence/Presence Detection: checks for the absence or presence of critical parts or part features after each production stage and at the end of the production process

- Barcode and OC Reading and Traceability: ensure barcodes and other important written information (e.g., optical characters) are present and legible to comply with traceability requirements (e.g., for medical and pharmaceutical use)

- Color Verification: identifies whether the part has the correct color(s) in the right areas

- Defect Detection: determines whether the part has functional or cosmetic flaws (e.g., sharp edge or angles, cracks, or embedded particulates)

- Part Verification: assesses whether the correct part or component has been added to the workpiece or production line

- Pattern Matching: detects whether the right product is running through the system and communicates any relevant production information to other facility systems for downstream operations

- Robotic Guidance: assists robotic lines in performing tasks (e.g., bin picking) without manual operator involvement by providing visual data about changing parts, production lines, and/or facility conditions

- Sorting: classifies parts as they pass by on the production line to sort them into predetermined categories downstream

WHY CHOOSE BIG SKY FOR YOUR VISION INSPECTION SYSTEM NEEDS?

At Big Sky Engineering, we have extensive experience designing and building custom automated manufacturing solutions, including vision inspection systems. All of our systems feature PLC controls and other advanced technologies to ensure they fully accommodate the requirements and restrictions of the intended facility. For examples of our work, view our past projects page.

To learn more about our vision inspection systems and other solutions or partner with us on an upcoming project, contact us or request a quote today. One of our customer service representatives will answer and address any questions or concerns you may have.