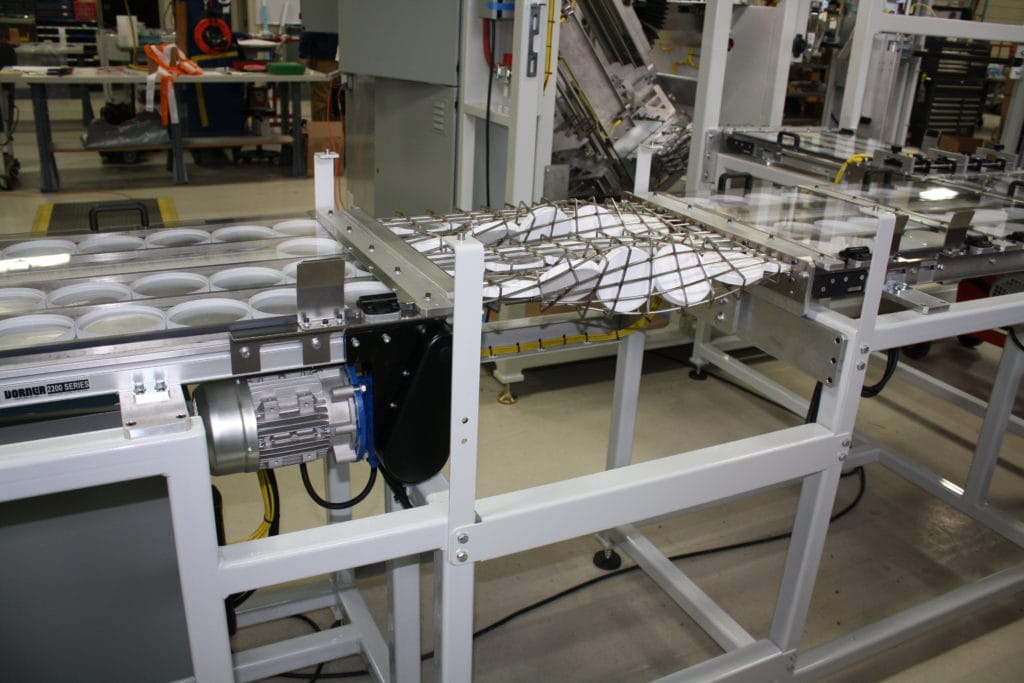

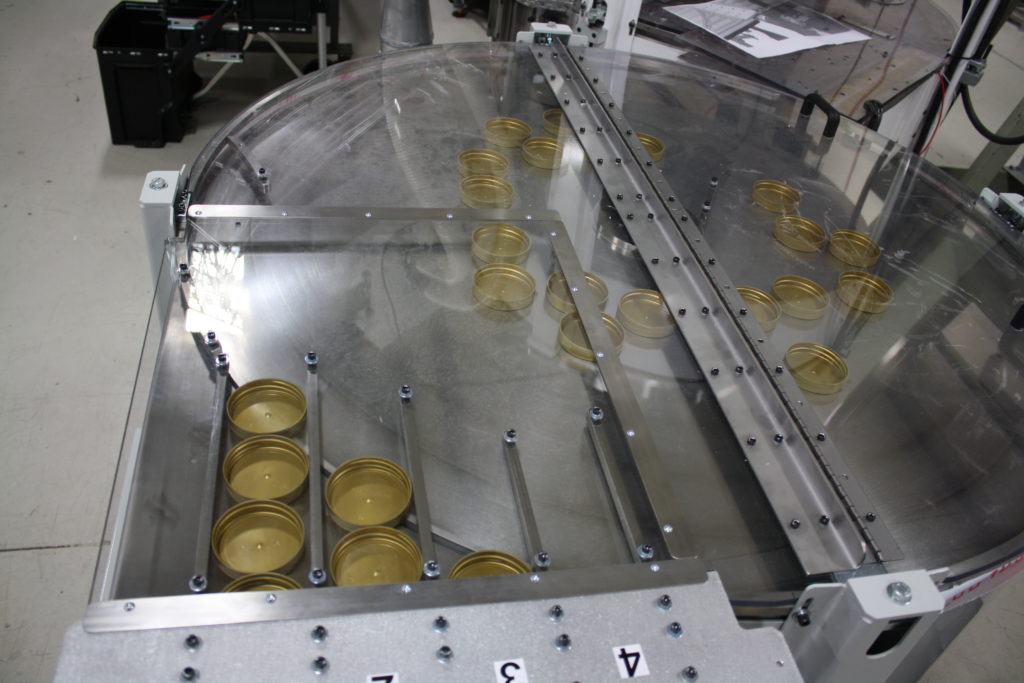

Conveyors

The conveyor type, material, length, width, and running rate are all important factors in moving plastic closures through the cap-lining process. CapTech has access to all major brands of industrial conveyor systems and can work with customers to determine the best choices for a particular application.