At CapTech Automation, innovative solutions are and always have been our core offering. All of our equipment is designed for efficiency and effectiveness, providing customers with a way to enhance their production operations by increasing throughput and decreasing costs.

With the industry knowledge of experts from Big Sky Engineering, we design, develop, and deliver a variety of automation and closure assembly solutions. One of our most popular products is our vision inspection systems. This equipment allows our customers to target and identify any part or process defect or concern before it becomes a major issue, resulting in increased production yields, lowered production costs, and many other benefits.

An Overview of Vision Inspection Systems

What Are Vision Inspection Systems?

In manufacturing operations, vision inspection systems—sometimes called machine vision systems—are used to visually detect and identify defects. They help ensure products meet the specifications outlined in the design as well as the quality standards defined by the manufacturer/customer.

How Do Vision Inspection Systems Work?

Vision inspection systems use a camera or multiple cameras along with video and lighting components to facilitate the measurement of parts, validation of necessary components, and verification of workpiece positioning. While basic systems require human operators to analyze the data they collect about products and make decisions accordingly, more advanced systems use computer software to automate the response to when a defect is detected.

Applications for Vision Inspection Systems

Vision inspection systems find use in the manufacturing operations of nearly every industry. In addition to detecting product defects, other common applications for these systems include:

- Identifying the absence/presence of targeted elements

- Matching patterns

- Reading barcodes and other unique product codes

- Recognizing/verifying optical characters or colors

- Sorting objects based on selected characteristics

Benefits of Vision Inspection Systems

There are many benefits to integrating vision inspection systems into a manufacturing facility, such as:

- Better part/process quality. Adding vision inspection systems to a production line reduces the risk that parts and products distributed to customers do not meet the necessary specifications and standards. Additionally, the information about parts and processes collected by the systems can be used to improve future production operations.

- Faster production speeds/shorter lead times. Vision inspection systems enable manufacturers to speed up production operations without increasing the risk of defective products going out to customers, which helps decrease lead times for product orders.

- Higher production yields. Since vision inspection systems allow for faster production speeds without sacrificing product/process quality, more units can be manufactured within the same timeframe.

- Lower production costs. Combining automated vision inspection systems with robotic manufacturing units enables products to be produced with fewer workers, resulting in lower labor costs.

- Safer worker conditions. Manufacturing operations often involve exposure to potentially hazardous materials and/or conditions. Vision inspection systems eliminate the need for human workers to handle manufactured objects directly, enabling them to stay away from health and safety hazards.

- Greater customer satisfaction. Both better product quality and shorter lead times can lead to greater satisfaction in customers.

Vision Inspection Systems at CapTech Automation

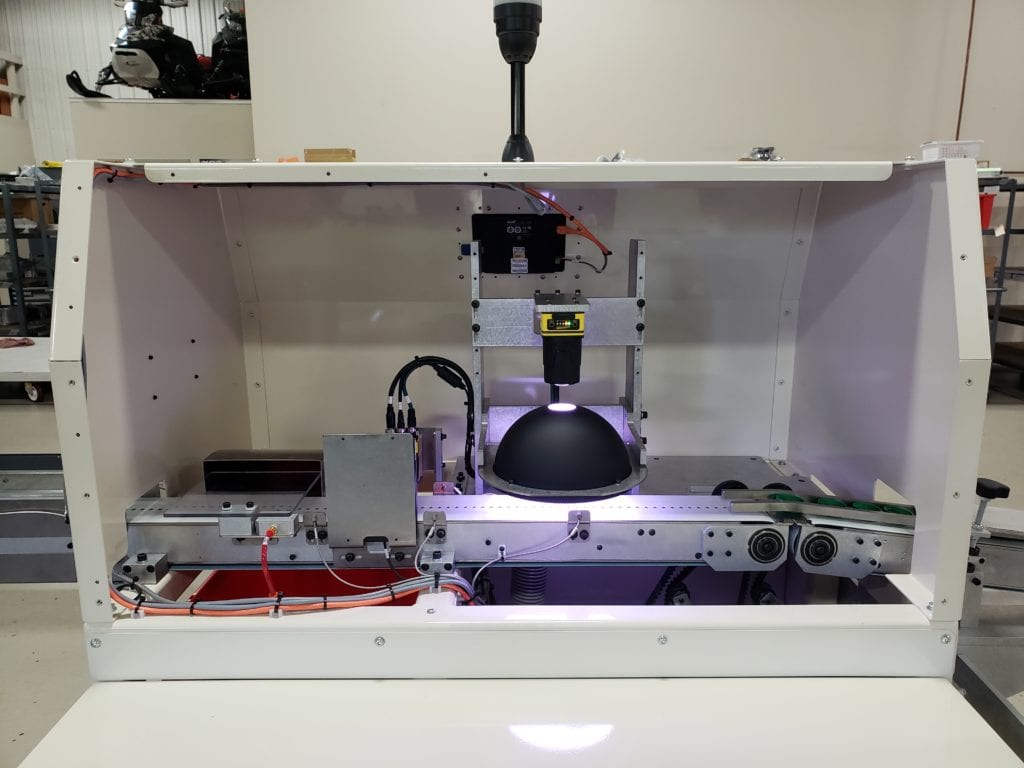

At CapTech Automation, our vision inspection systems are used to validate different properties of liner discs in lined caps and, for some instances, aspects of the molded closure. Common attributes inspected include liner-disc presence, mooned liner disc, off-center liner disc, and tape splices. The systems accommodate the inspection of ABS, polyethylene, polypropylene, and many other specialized materials.

Some of the standard features of our vision inspection systems include:

- A camera to detect and identify defects

- A conveyor to pass a single line of caps underneath the camera

- A vacuum belt to prevent slipping during the process (inclusion depends on the processing rate and cap size)

- Integrated backlighting to enhance defect detection

- Air jet ejectors to remove defective items from the line without slowing down production

Why Partner With CapTech Automation

The CapTech Automation team has considerable experience integrating and programming custom vision inspection systems from reputable suppliers, such as Cognex, Keyence, and Omron. Our relationships with these and other OEMs ensure each customer gets a high-quality vision system solution at the best possible price. Additionally, our constant evaluation of the evolution of vision inspection equipment and optical sensors allows us to design and develop more advanced solutions ahead of our competition.

Quality Vision Inspection Systems From CapTech Automation

For manufacturing operations where quality and efficiency are critical, vision inspection systems are an ideal solution. They allow industry professionals to identify and detect defects accurately and quickly before they go to market.

If you need a vision inspection system for your facility, turn to the experts at CapTech Automation. For additional information about our vision inspection systems or assistance finding one that meets your needs, contact us or request a quote today.