Stacking/Packing Products

Stacking/Packing Products

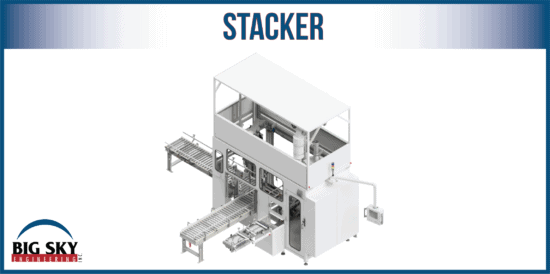

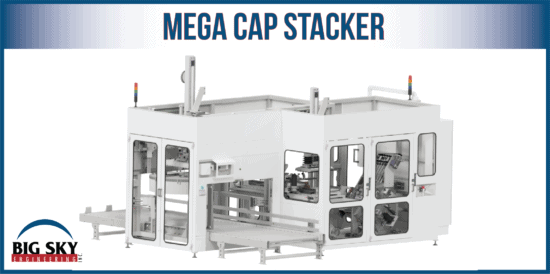

CapTech Automation has the widest array of final closure packing automation in the industry. We have engineered solutions for layer packing, log packing, and bulk feeding. We can pack your closures into cartons or gaylords. Our systems are designed to minimize changeover time with quick-change fixtures and tooling.

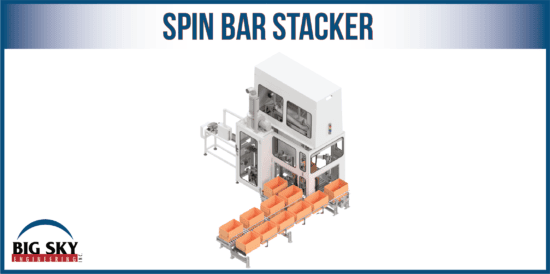

The high-speed log stacker can pack closures with or without nesting features using alternating closure orientation and spin bars to stabilize the logs. The system stacks up multiple logs of caps simultaneously then a gantry equipped with a vacuum arm tool picks the logs and transfers them to the appropriate carton. These systems are capable of speeds up to 1500 caps per minute, based on closure size/shape and packing configuration.

CapTech also has solutions for layer-packing applications. A similar gantry pick and place head is used to transfer an entire layer of closures into the case at once. Both the log stacker and the layer packer systems use regenerative blowers to generate the vacuum required to transfer the closures to the cases.

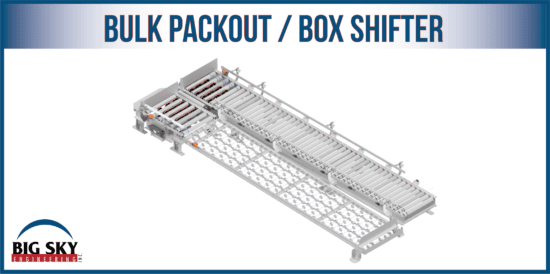

Cases and Totes are controlled automatically by powered-roller conveyors to position a new empty container in the fill position. When in place, box locators engage the case to ensure correct positioning and that any liner stays in the case. Filled cartons are automatically ejected to either an outfeed conveyor or a declined gravity roller.