Don’t overlook the importance of choosing the right type of parts orienting and feeding system for your products and operation. The best choice for a particular closure automation program should provide the best combination of reliability, production rates, ability to handle the range of closures required, ease of change-overs, and operating costs.

CapTech Automation supplies a wide variety of closure orientation and feed systems:

- Robotic parts are taken directly from the injection molding machine

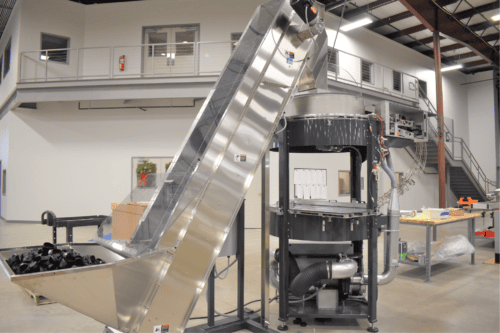

- Bulk hopper elevators to feed bulk parts to an orientor system

- Vibratory bowl cap feeders

- Rotary bowl cap feeders

- Waterfall-style cap feeders

- Proprietary High-Speed Vacuum-Belt sorters for closure sizes 38mm to 135mm

Closure feed rates are affected by a variety of factors such as aspect ratio, diameter, and overall design. Lower production rates are typically less challenging than high-speed systems. Maximum feed rates for small diameter closures can be as high as several thousand caps per minute, and large diameter caps up to approximately one thousand caps per minute.

All cap feeder types can be customized to meet customer requirements, and are typically tied into the centralized system HMI to coordinate the overall system operation. CapTech has excellent expertise in the design and construction of custom cap shuts, conveyor covers, and lane dividers. Often included are sensor systems for upside-down caps, low-conveyors, and other operational aspects.