Punch die sets—also referred to as punch and die sets—are used in fabrication operations to cut out components from sheet materials (e.g., metal, plastic, or paper). At Captech Automation, we offer punches and dies for the production of liners for caps and containers.

Uses of Punch Die Sets

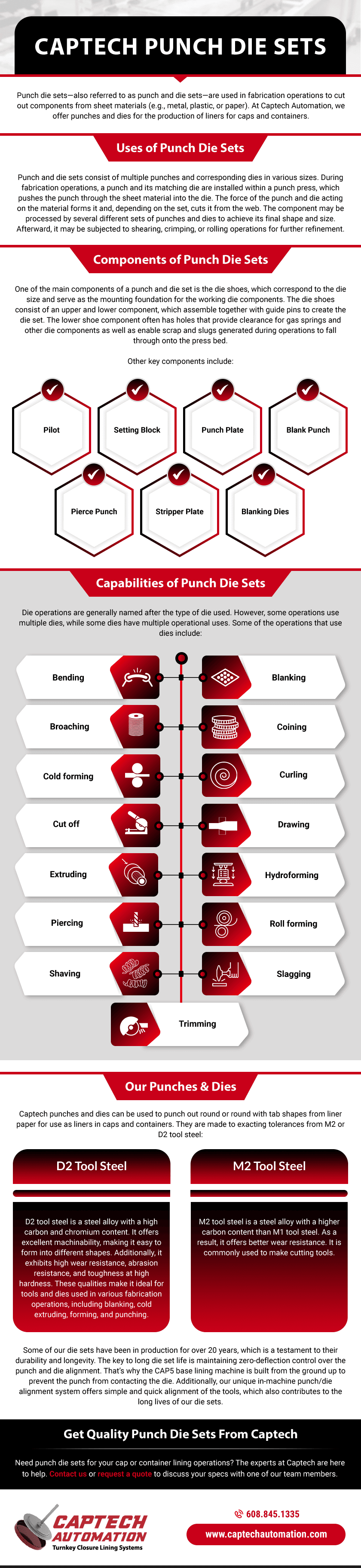

Punch and die sets consist of multiple punches and corresponding dies in various sizes. During fabrication operations, a punch and its matching die are installed within a punch press, which pushes the punch through the sheet material into the die. The force of the punch and die acting on the material forms it and, depending on the set, cuts it from the web. The component may be processed by several different sets of punches and dies to achieve its final shape and size. Afterward, it may be subjected to shearing, crimping, or rolling operations for further refinement.

Components of Punch Die Sets

One of the main components of a punch and die set is the die shoes, which correspond to the die size and serve as the mounting foundation for the working die components. The die shoes consist of an upper and lower component, which assemble together with guide pins to create the die set. The lower shoe component often has holes that provide clearance for gas springs and other die components as well as enable scrap and slugs generated during operations to fall through onto the press bed.

Other key components include:

- Pilot

- Setting block

- Punch plate

- Blank punch

- Pierce punch

- Stripper plate

- Blanking dies

Capabilities of Punch Die Sets

Die operations are generally named after the type of die used. However, some operations use multiple dies, while some dies have multiple operational uses. Some of the operations that use dies include:

- Bending

- Blanking

- Broaching

- Coining

- Cold forming

- Curling

- Cut off

- Drawing

- Extruding

- Hydroforming

- Piercing

- Roll forming

- Shaving

- Slagging

- Trimming

Our Punches & Dies

Captech punches and dies can be used to punch out round or round with tab shapes from liner paper for use as liners in caps and containers. They are made to exacting tolerances from M2 or D2 tool steel:

- D2 tool steel is a steel alloy with a high carbon and chromium content. It offers excellent machinability, making it easy to form into different shapes. Additionally, it exhibits high wear resistance, abrasion resistance, and toughness at high hardness. These qualities make it ideal for tools and dies used in various fabrication operations, including blanking, cold extruding, forming, and punching.

- M2 tool steel is a steel alloy with a higher carbon content than M1 tool steel. As a result, it offers better wear resistance. It is commonly used to make cutting tools.

Some of our die sets have been in production for over 20 years, which is a testament to their durability and longevity. The key to long die set life is maintaining zero-deflection control over the punch and die alignment. That’s why the CAP5 base lining machine is built from the ground up to prevent the punch from contacting the die. Additionally, our unique in-machine punch/die alignment system offers simple and quick alignment of the tools, which also contributes to the long lives of our die sets.

Get Quality Punch Die Sets From Captech

Need punch die sets for your cap or container lining operations? The experts at Captech are here to help. Contact us or request a quote to discuss your specs with one of our team members.