Material handling refers to the movement of materials within and between different areas of a facility for production and assembly projects. While the process can be performed manually, using automated material handling systems can make operations more efficient, resulting in significant time, labor, and cost savings for the facility. The systems utilize computerized controls and robotic elements to move materials with little to no human involvement.

What Is Automated Material Handling?

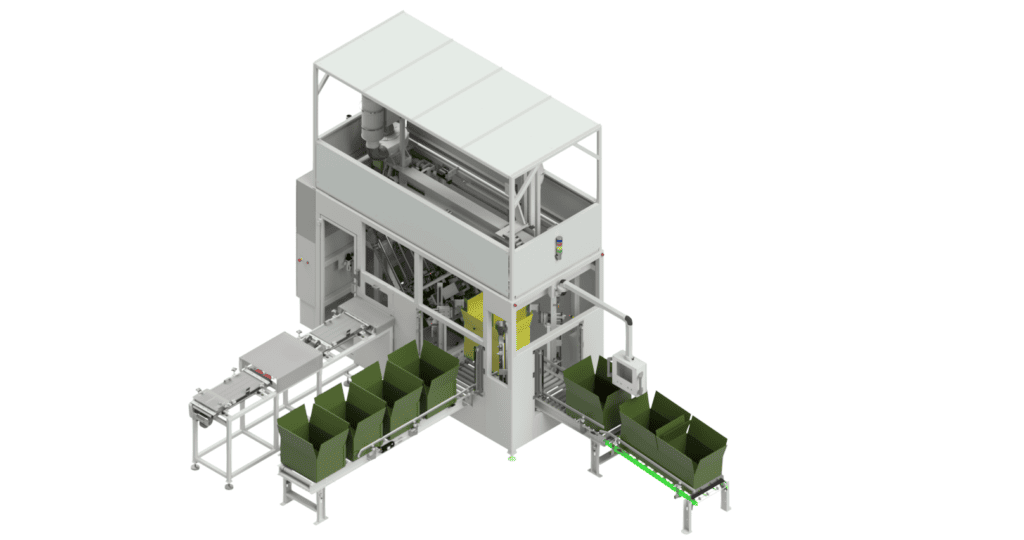

Automated material handling operations use automation technology to reduce or eliminate the need for human workers to locate, sort, and move materials to where they need to go. Typical elements in an automated material handling system include:

- Mechanical components, such as bins, check-in systems, conveyors, singulators, sorters, stackers, totes, automated guided vehicles (AGVs) and trolleys

- Identification components, such as barcode, RFID, near-field communication, optical character recognition (OCR), and ultra-wide band indoor tracking systems

Together, these elements enable materials to be retrieved, moved, and stored automatically at the push of a button.

5 Benefits of Automated Material Handling Systems

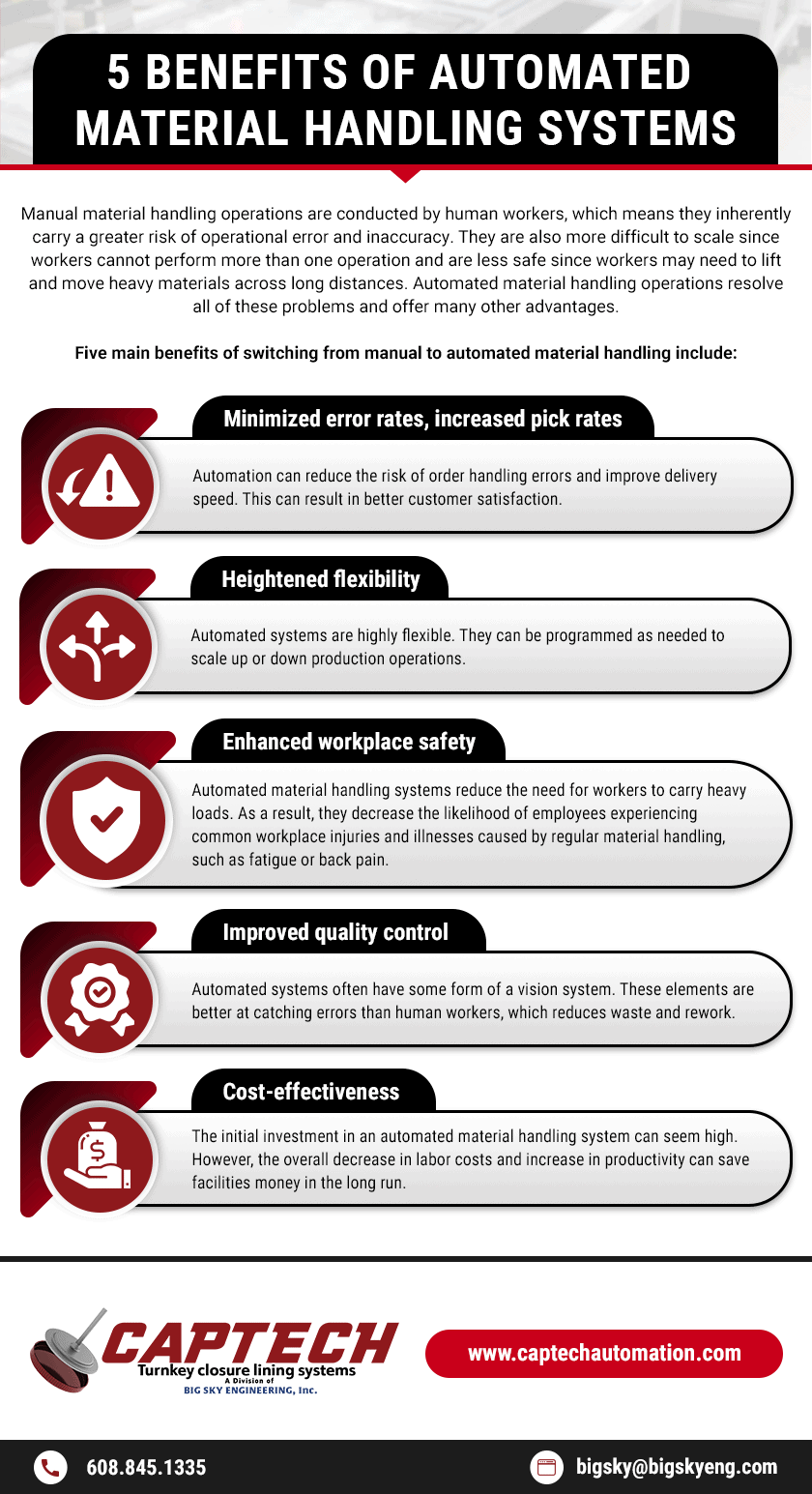

Manual material handling operations are conducted by human workers, which means they inherently carry a greater risk of operational error and inaccuracy. They are also more difficult to scale since workers cannot perform more than one operation and are less safe since workers may need to lift and move heavy materials across long distances. Automated material handling operations resolve all of these problems and offer many other advantages.

Five main benefits of switching from manual to automated material handling include:

- Minimized error rates, increased pick rates. Automation can reduce the risk of order handling errors and improve delivery speed. This can result in better customer satisfaction.

- Heightened flexibility. Automated systems are highly flexible. They can be programmed as needed to scale up or down production operations.

- Enhanced workplace safety. Automated material handling systems reduce the need for workers to carry heavy loads. As a result, they decrease the likelihood of employees experiencing common workplace injuries and illnesses caused by regular material handling, such as fatigue or back pain.

- Improved quality control. Automated systems often have some form of a vision system. These elements are better at catching errors than human workers, which reduces waste and rework.

- Cost-effectiveness. The initial investment in an automated material handling system can seem high. However, the overall decrease in labor costs and increase in productivity can save facilities money in the long run.

Common Automated Material Handling System Applications

Material handling operations can be automated in many ways depending on the needs of the facility. Some of the most popular automated material handling solutions are:

- Automated storage retrieval systems (AS/RS). These systems are designed to handle the storage and retrieval of materials. Manufacturers rely on the speed and accuracy of these systems for production, assembly, and retail applications.

- Automated guided vehicles (AGVs). These computer-controlled machines travel across the floors of facilities without human guidance or interference. They are used to transport materials, pull trailers, and move equipment.

- Material handling robots. These machines are utilized for a wide range of applications. They generally have articulated arms that can hold and/or use a material or tool.

- Stackers. These machines create piles of bulk material by moving from one point to another on a rail system.

Partner With CapTech Automation for Your Automated Material Handling Systems

Automated material handling systems offer a number of benefits to industrial and commercial facilities. If you’re ready to get started on your solution, the experts at CapTech Automation are here to help. We offer custom automation solutions, including fully automated and semi-automated equipment, to help customers produce higher quality products in greater volumes at lower costs. Contact us today to learn more about our capabilities. Request a quote to discuss your equipment needs with one of our team members.