Closure Lining Machines

Closure Lining Machines

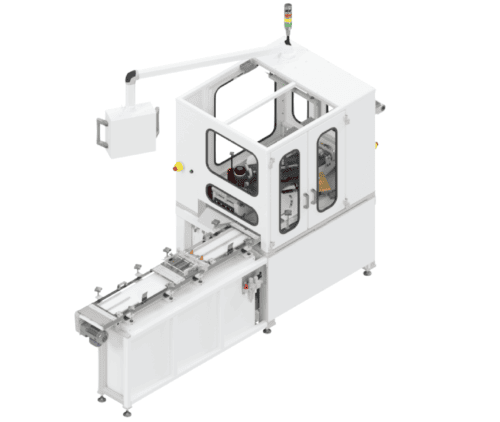

FEATURES

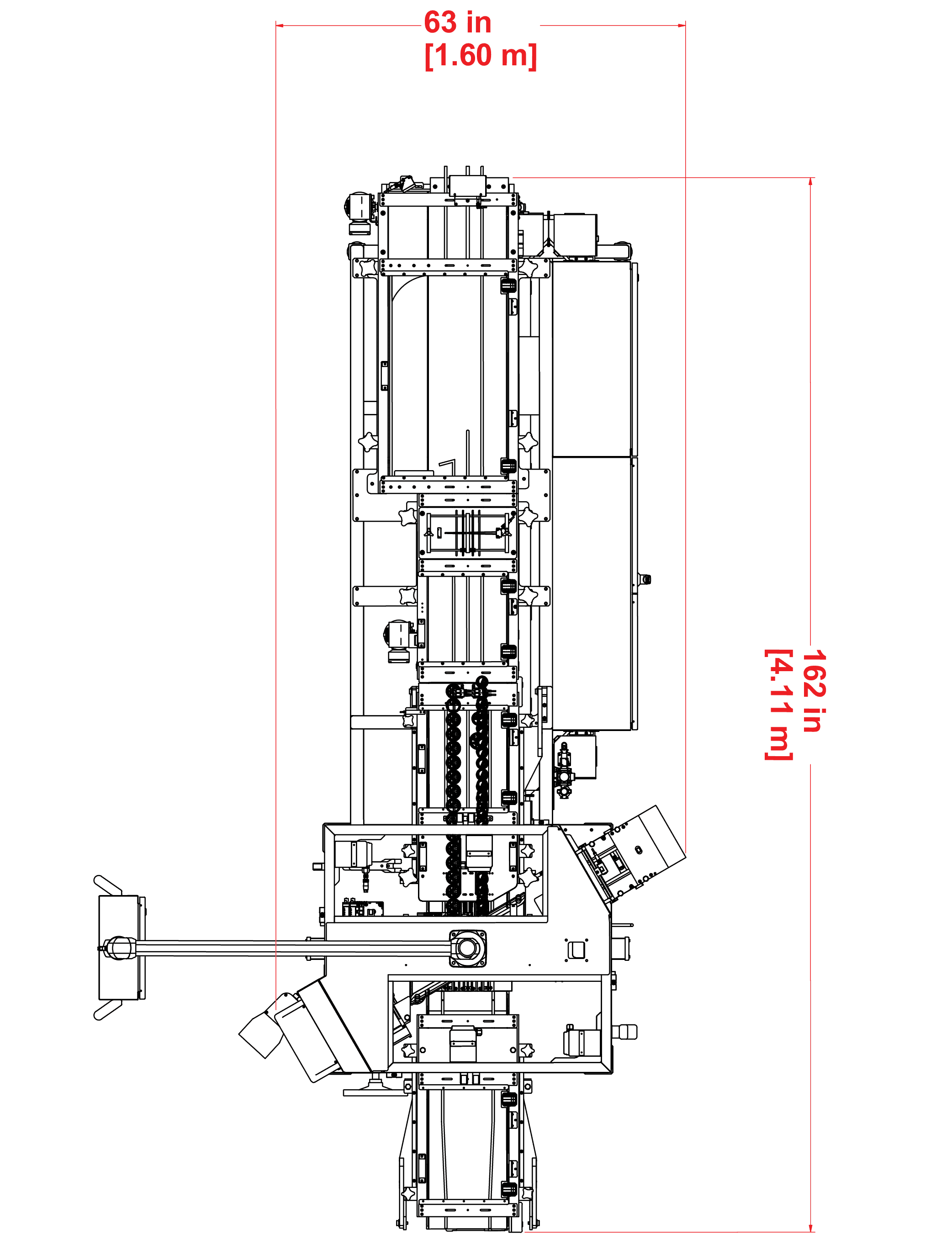

- 1-up, 2-up, 3-up or 4-up

- 150RPM Punch Cycle Rate

- Compatible with Lining Material Strip Width Up to 7 in

BENEFITS

- Exclusive State of the Art Electronic Components

- Heavy Duty Steel Constructed Frames

- Plastic Chain Conveyor Systems

- Heavy Duty Interlocked Access Doors

- Advanced & Comprehensive Operator Control Systems.

- Robust Clockwork Tooling System

- Internal Lining Chopper Assembly Mechanism

- Automatic Splice Detection

- Advanced Upside-Down Cap Detection

- Cutting-Edge Safety Systems

- 480VAC – 3 Phase – 60A

- Made in the USA

OTHER

- Cap Feeders

- Cap Sorters

- Vision systems

- Pack Out Systems

- Cap Stackers

- Accumulators

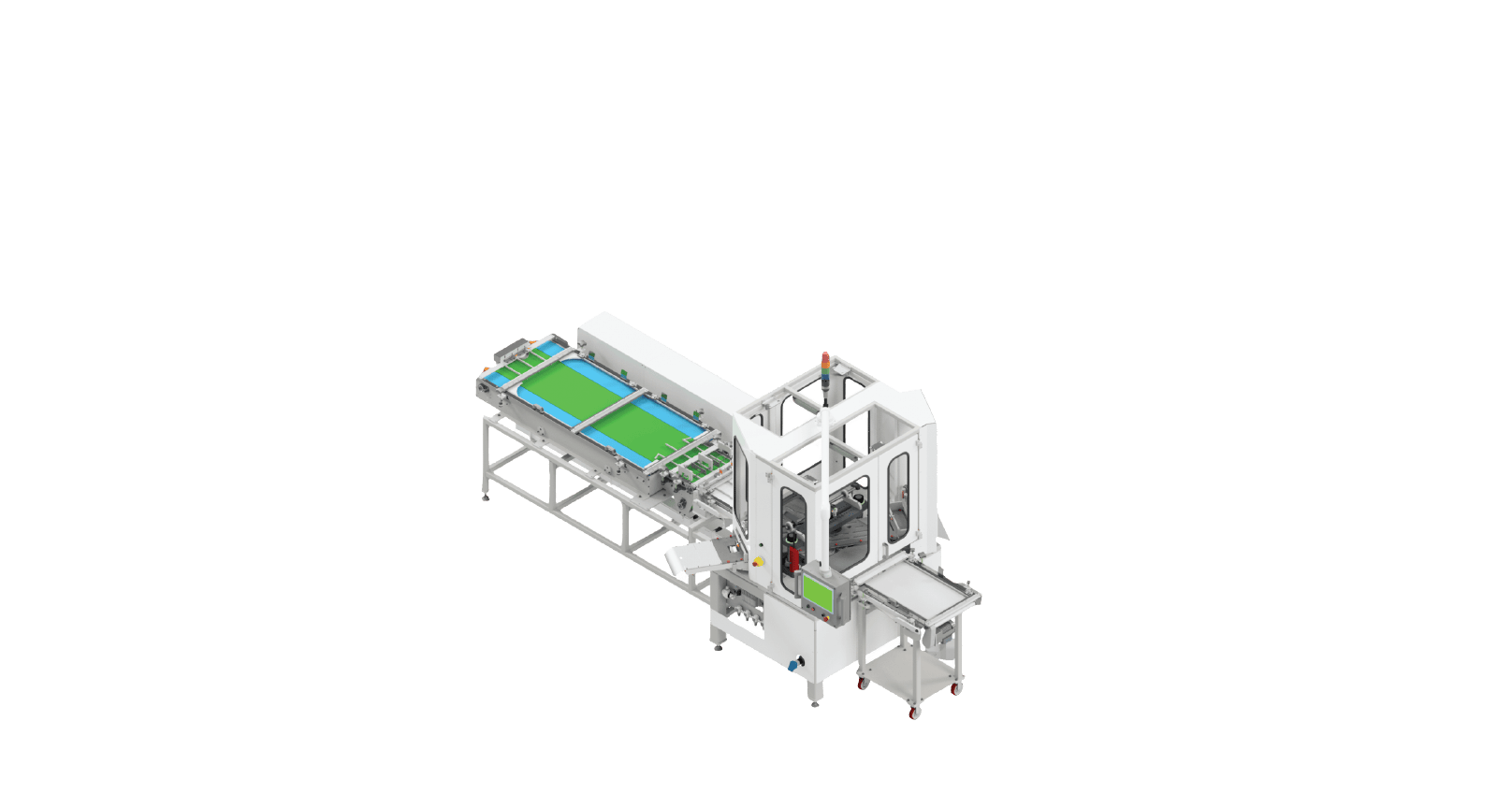

FEATURES

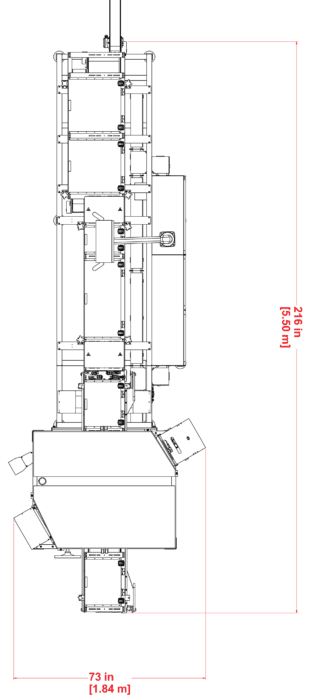

- 2-up, 3-up, 4-up, 5-up, 6-up, 7-up

- 150RPM Punch Cycle Rate

- Compatible with Lining Material Strip Width Up to 11 in

BENEFITS

- Cap Feeders

- Cap Sorters

- Vision systems

- Pack Out Systems

- Stackers

- Accumulators

OTHER

- Exclusive State of the Art Electronic Components

- Heavy Duty Steel Constructed Frames

- Plastic Chain Dual Recirculating Conveyor Systems

- Heavy Duty Interlocked Access Doors

- Advanced & Comprehensive Operator Control Systems.

- Robust Clockwork Tooling System

- Internal Lining Chopper Assembly Mechanism

- Automatic Splice Detection

- Advanced Upside-Down Cap Detection

- Cutting-Edge Safety Systems

- 480VAC – 3 Phase – 60A

- Made in the USA

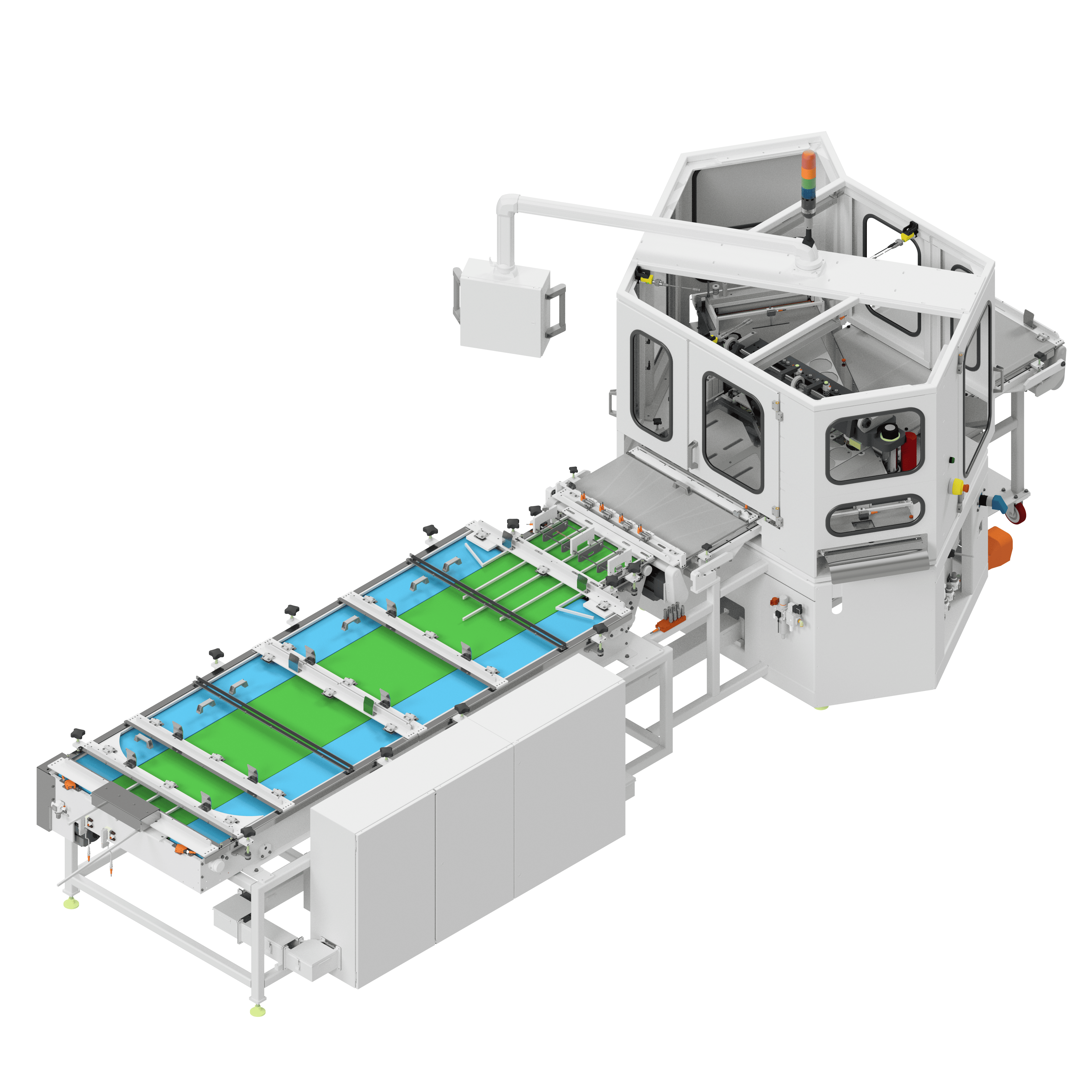

FEATURES

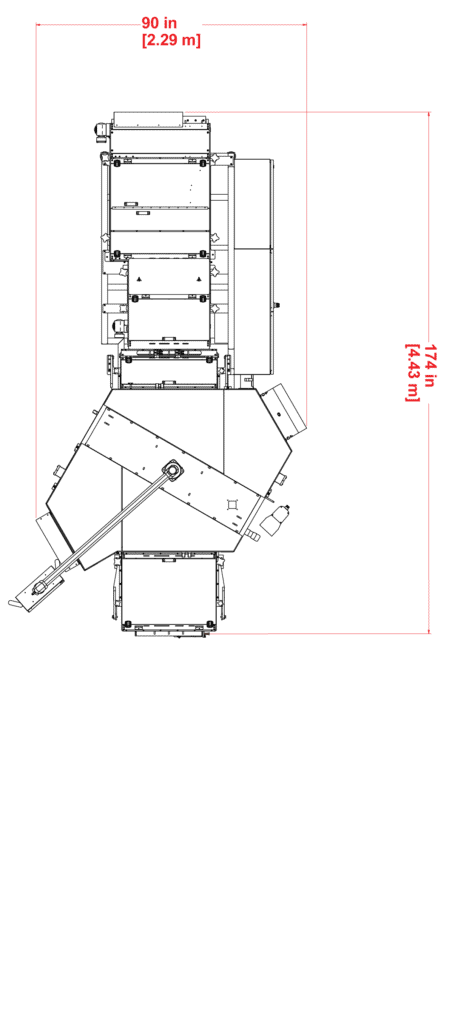

- 3-up,4-up,5-up,6-up,7-up,8-up,9-up,10-up

- 150RPM Punch Cycle Rate

- Compatible with Lining Material Strip Width Up to 15 in

BENEFITS

- Cap Feeders

- Cap Sorters

- Vision systems

- Pack Out Systems

- Cap Stackers

- Accumulators

OTHER

- Exclusive State of the Art Electronic Components

- Heavy Duty Steel Constructed Frames

- Plastic Chain Dual Recirculating Conveyor Systems

- Heavy Duty Interlocked Access Doors

- Advanced & Comprehensive Operator Control Systems.

- Robust Clockwork Tooling System

- Internal Lining Chopper Assembly Mechanism

- Automatic Splice Detection

- Advanced Upside-Down Cap Detection

- Cutting-Edge Safety Systems

- 480VAC – 3 Phase – 60A

- Made in the USA

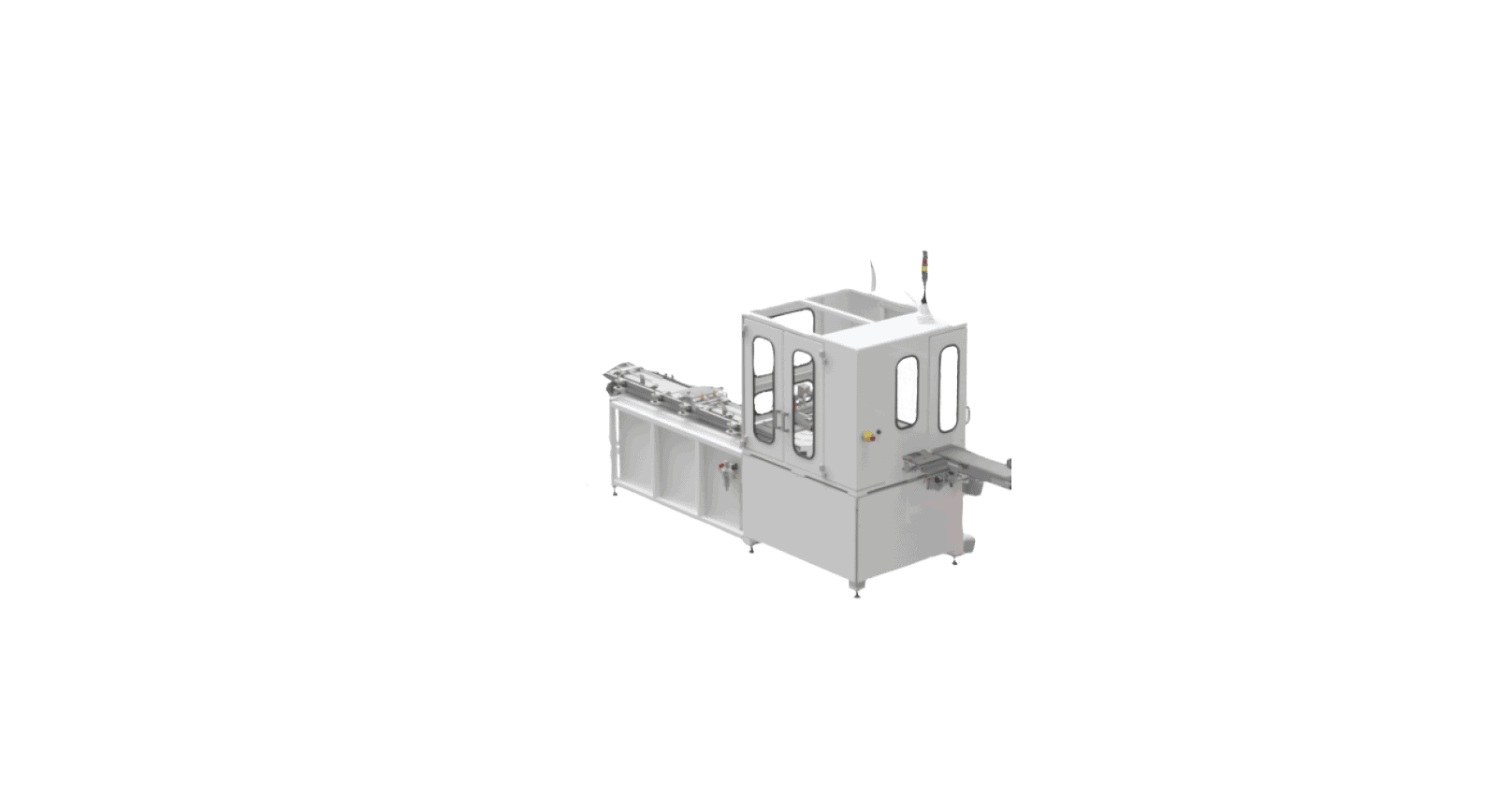

FEATURES

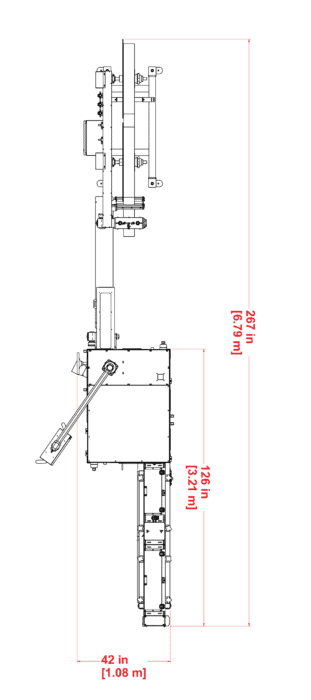

- 1-up

- 150RPM Punch Cycle Rate

- Compatible with Lining Material Strip Width Up to 7 inch

BENEFITS

- Cap Feeders

- Cap Sorters

- Vision systems

- Pack Out Systems

- Stackers

- Accumulators

OTHER

- Exclusive State of the Art Electronic Components

- Heavy Duty Steel Constructed Frames

- Heavy Duty Interlocked Access Doors

- Advanced & Comprehensive Operator Control Systems.

- Robust Clockwork Tooling System

- Internal Lining Chopper Assembly Mechanism

- Automatic Splice Detection

- Advanced Upside-Down Cap Detection

- Cutting-Edge Safety Systems

- Compact Machine Design

- 480VAC – 3 Phase – 60A

- Made in the USA

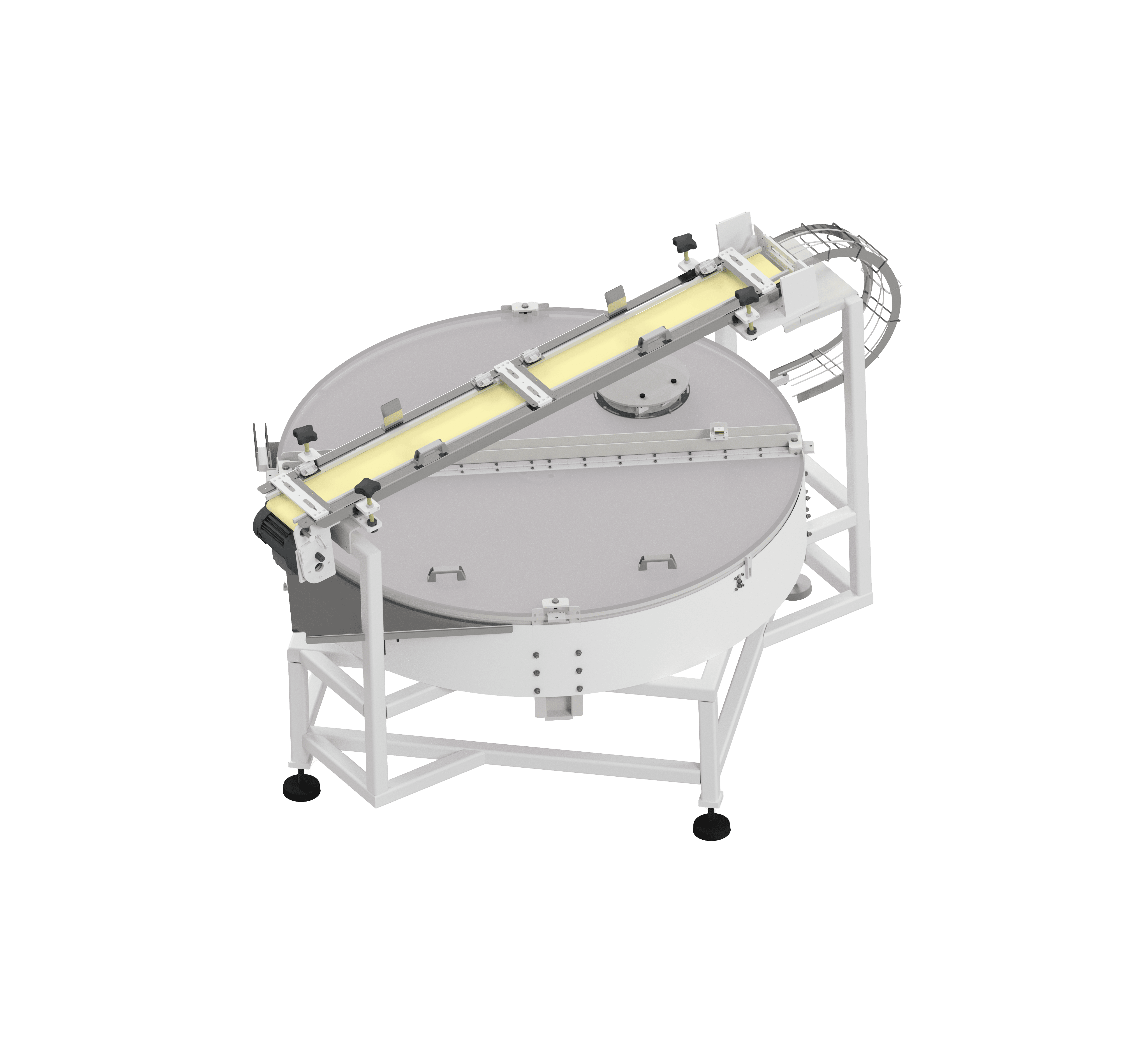

OUR FLAGSHIP CAP5 CLOCKWORK FAMILY OF CAP LINING MACHINES

At CapTech, we also specialize in creating high-performance CAP5 Clockwork lining machines. This technology places liners in multiple lanes of closures simultaneously. By bringing the lining material across at an angle we are able to maximize the roll width, allowing more of the master roll to be used which directly translates to savings. The lining material is also cut and inserted in one step, reducing the amount of tooling required. These units are gentle, straightforward, and can handle multiple functions.

The punch ram is gas-spring balanced for smooth operation and control, and intra-cycle process control systems are built into the machinery for early detection and prevention of defects. We build and provide four different sizes of our CAP5 Clockwork machine systems based on throughput needs.

The CAP5 Clockwork machines are also designed for multiple sizes of closure per machine, with easy and fast changeover.

TYPICAL INDUSTRY CLOSURE LINING MACHINES

Choosing the proper closure lining machine system is essential to ensure you are using the right technology for your cap type and materials. Each system can be customized to fit a company’s assembly, inspection, testing, and orienting needs. At CapTech, we design and provide all of the following closure lining machine systems:Indexing Star-Wheel Type Cap Lining Machines

Indexing star-wheel type cap lining machines can handle precise counting and indexing operations. This relatively slow machine places closures in a carousel to perform the lining operations. With each index, the wheel turns one position and the parts are carried through stations in fixtures. The finished parts are ejected into a bin or onto a conveyor. This machinery is excellent for organizing cap lining operations in smaller batches or groups.Rotary Die Type Cap Lining Machines

Rotary die-cutting is a fast, continuous cutting process. Cap lining machines enabled with rotary dies can quickly cut the customized perforations for any predetermined cap design, and the rest of the machinery can orient, place, and securely seal the cap with the liner. Due to the relatively high tooling cost. This machine style is excellent for fast, high-volume processing of a single design at a time.Shuttle-Type Cap Lining Machines

Shuttle-type cap lining machines can work with virtually any size, style, or shape of cap lining. They can also employ different techniques, such as interference fits and hot melt glue, to secure the lining in the cap and ensure optimal performance. These machines can work with circular linings and linings with pull tabs.BENEFITS OF USING CAP LINERS

Cap lining machines offer various essential functions and benefits, including:

- Authenticating product integrity. The presence of a well-sealed cap liner acts as a guarantee that a container has not been opened or contaminated after the filling and closing processes were completed. Liners can also display the date of sealing or the best by date.

- Enhancing consumer confidence. When consumers see a fully sealed container, they are assured of the product’s freshness and lack of contamination. For liquid and semi-liquid products, the seal also prevents the product from making the interior of the lid dirty, which further enhances the consumer’s experience.

- Graphic communication and promotion. Cap liners can be colorful, engaging, and promotional. Manufacturers can print logos, fun facts, coupons, and other text or image selections on top of cap liners to further engage audiences after purchase.

- Preserving freshness. The physical barrier of a cap liner, especially one that is fully sealed to the rim of the container, halts or slows the process of oxidation, allowing the product to remain fresh for a longer period of time.

- Preventing leakage. Cap liners prevent leakage and spills during transportation and commercial storage to ensure fully intact products when distributed to consumers.

- Preventing product contamination. Cap liners prevent contaminants such as moisture, dust, gaseous chemicals, and other unwanted substances from degrading or mixing with the product.

INDUSTRIES THAT DEPEND ON

CLOSURE LINING MACHINES

Any industry that produces consumable products benefits from reliable closure lining machines that seal their products into their containers for freshness and purity. The three key industries that rely on this equipment are:

Food & Beverage

Pharmaceutical

Cosmetics

Food & Beverage

Pharmaceutical

Cosmetics

CAPTECH PROVIDES TURNKEY CLOSURE LINING SYSTEMS

Closure lining machines are essential for ensuring freshness, while offering customized lining graphics and control over the entire sealing process. At CapTech, we specialize in providing the most advanced and most comprehensive line of turnkey closure lining systems in North America.

Our broad experience in the design and development of custom closure lining machines combined with our extensive industry expertise makes the ideal partner for your closure lining solutions. To learn more about our capabilities, or to get started on your custom system, contact us or request a quote today.

| CAP5 Machine Model | Maximum Lining Material Strip Width | Maximum Die-Set Cavitation (38mm) | Maximum Die-Set Cavitation (110mm) |

|---|---|---|---|

| CAP5-7 | 7” | 4-up | 1-up |

| CAP5-11 | 11” | 7-up | 2-up |

| CAP5-16 | 15” | 10-up | 3-up |

Big Sky Engineering is a dedicated team of custom industrial automation specialists.

Download Datasheet

To download a datasheet including dimensions and specs, please fill out the form below.

"*" indicates required fields